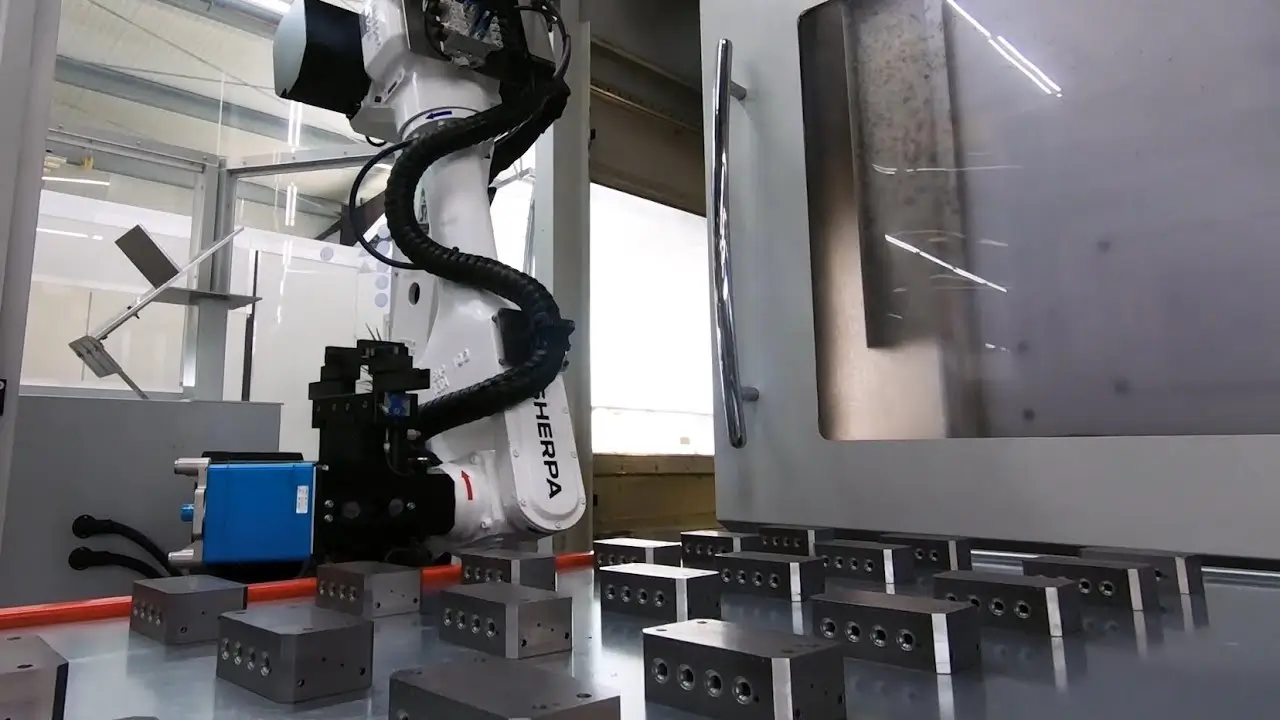

Innovative workpiece detection with 3D camera laser system

The integrated 3D laser Vision System recognizes workpieces regardless of shape, position or orientation. Compared to mechanical drawer systems with fixed grids, this solution offers significantly more flexibility and reduces the effort involved in preparation.

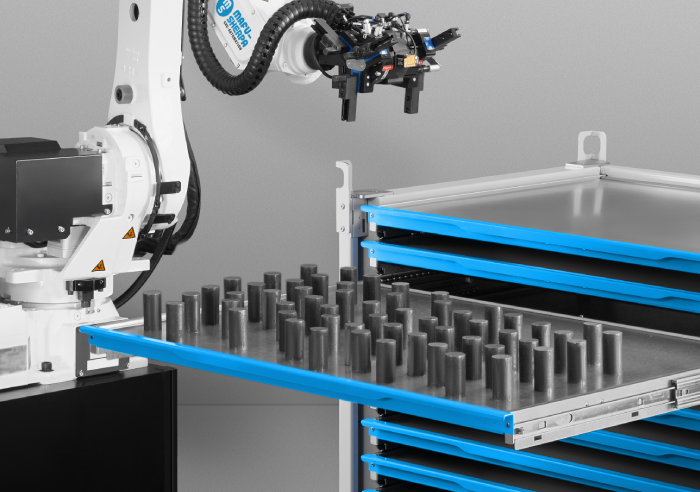

Faster changeover in less than 5 minutes when changing workpieces

Workpieces can be changed in less than five minutes. All you need to do is briefly teach in the New Part. There is no need for mechanical grids or grating. This saves valuable time and makes automation economical even for frequently changing jobs.

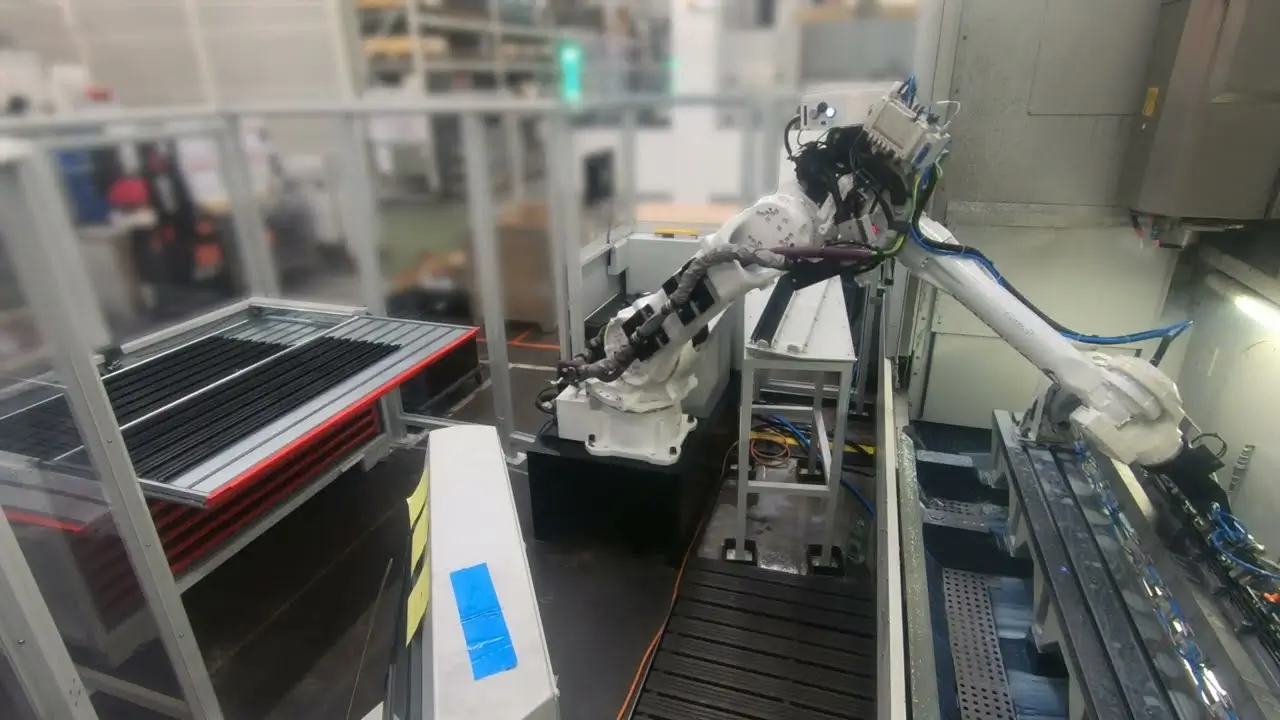

Flexible material provision via SpaceBox, Table Trolleys or Pallets

Pallets, Table Trolleys or SpaceBox - the material supply is freely selectable. The Vision System automatically recognizes the workpieces without the need for special fixtures. This keeps production flexible and adaptable.

Simple operation without robot programming knowledge

It is operated via an intuitive dialog control with touch interface. New workpieces can be taught in just a few minutes - without the need for robot programming or external specialists. This makes the automation particularly user-friendly and quick to set up.