Universal robot solution for all Okuma machine types

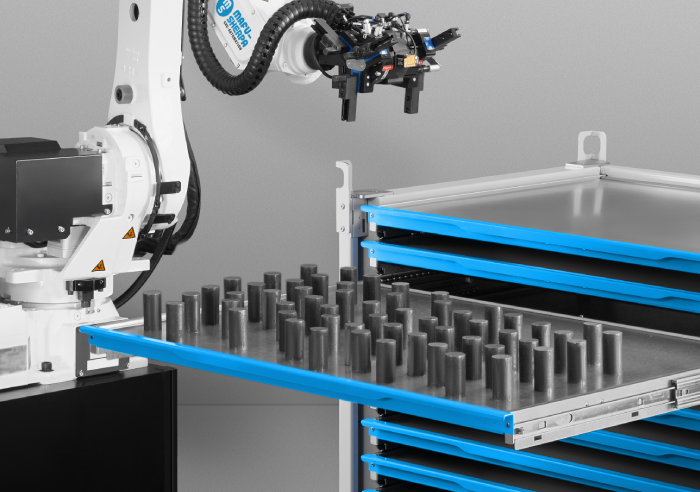

MAFU-SHERPA offers a precise and flexible automation solution for Okuma lathes. With the SherpaLoader®, loading is completely taken over by a robot arm - from workpiece feeding to removal of the finished parts. The systems enable economical production around the clock. The robot takes your Okuma to a New level of productivity.

How it works

On the Okuma SimulturnLU300-M, the SherpaLoader® T25 takes over the complete workpiece handling. Rings are provided via Table Trolleys, automatically aligned and inserted into the spindle. Automated cleaning ensures consistent quality and reduced non-productive times. You can find more information and a video here.

The Okuma LB3000 EX III CNC lathe has already been successfully automated with the SherpaLoader® T225. The robot arm ensures maximum productivity and enables continuous 24/7 operation. Workpieces weighing up to 175 kg* can be loaded safely with the automation. You can find a demonstration of the automation in the video here.

The SherpaLoader® systems can be used universally for all common Okuma models. Whether light chuck parts, medium-weight rings or large workpieces - automation increases productivity and reduces costs in any production environment.

The loading of an Okuma machine by the SherpaLoader® is completely automatic. Workpieces are recognized by the camera, picked up and precisely inserted into the spindle. As a result, the machine runs without interruption, while manual intervention is no longer necessary. The result is significantly higher spindle utilization. Production capacities are optimally utilized and production can be stable and efficient over Lengthwise periods - even in unmanned operation.

Automation replaces time-consuming manual work during workpiece feeding. Employees no longer have to perform repetitive tasks and can concentrate on value-adding activities. This noticeably reduces personnel costs and increases productivity at the same time. More is produced with less effort and production remains reliable even when there is a shortage of skilled workers.

The robot arm works with consistent precision. Workpieces are positioned exactly and handled safely, regardless of their weight or shape. This results in consistent production quality across all series. Rejects are reduced, rework is minimized and process reliability is permanently increased.

With SherpaLoader® automation, Okuma machines can produce around the clock - regardless of shift times or personnel availability. This means maximum capacity utilization, consistent quality and a significant reduction in unit costs.

The SherpaLoader® relieves skilled workers of monotonous loading activities and reliably takes over these tasks. This allows qualified employees to use their time for value-adding activities while the Okuma machine continues to work automatically. This actively compensates for the shortage of skilled workers and ensures long-term competitiveness.

The SherpaVision® 3D laser Vision System detects workpieces automatically and precisely. There is no need for complex fixtures, as the parts are picked up directly where they are provided. This saves time and reduces sources of error.

Workpieces can be changed in less than five minutes. Only the gripper dimensions are adjusted, no complex retooling is necessary. This means more production time and less downtime.

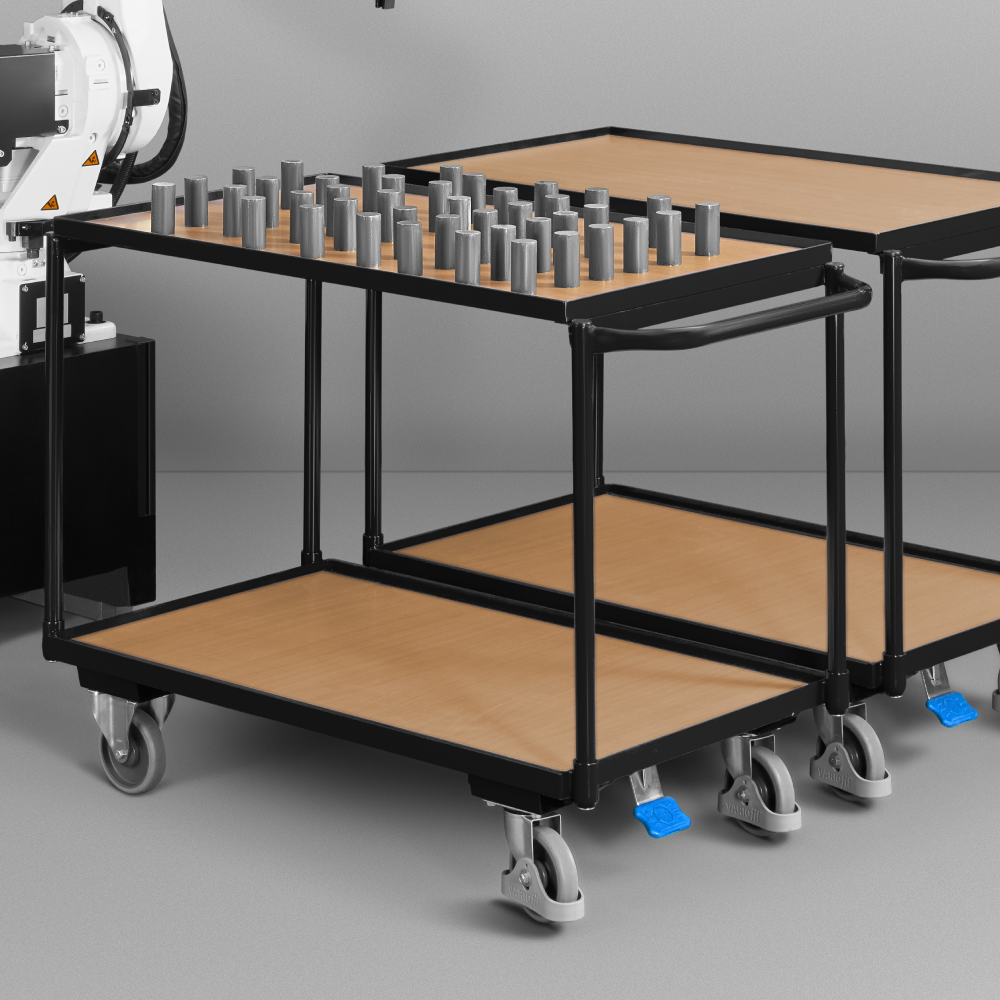

Whether small batch sizes or heavy workpieces - material provision is flexible. SpaceBox, Table Trolleys or Pallets can be used as required. This means that automation can be adapted to any production situation.

It is controlled via an intuitive touch display. Clear symbols and simple inputs make operation easy to understand. Programming knowledge for OSP is not required.

The SherpaLoader® T7 is ideal for smaller turned parts on Okuma LB machines. It performs precise loading directly at the chuck and reduces manual intervention.

The SherpaLoader® T12 extends automation to workpieces up to 8 kg* - perfect for users who want to operate their Okuma LB series more flexibly.

*Handling weight depending on workpiece center of gravity

The SherpaLoader® T25 and SherpaLoader® T50 models are designed for Okuma lathes with medium workpiece weights. They enable stable and reliable automation of turned parts without limiting the flexibility of production.

SherpaLoader® T88 and SherpaLoader® T225 offer the right solution for Okuma lathes that work with particularly heavy parts.

The Genos L series benefits from the flexible material feed of the SherpaLoader®. It is particularly suitable for small batch sizes and can automatically edit both shafts and inserts. Automatic unloading is possible when feeding with a bar loader. Workpieces do not have to be stackable, and the compact design allows flexible installation even in confined spaces.

Thanks to automation with SherpaLoader®, the LB series achieves a high workpiece capacity in a very small space. In addition to small batch sizes, inserts, shafts, semi-finished products and cast parts can also be handled automatically. Robots with a workpiece weight of up to 73 kg* enable the safe turning of heavy parts. Retrofitting is carried out from a single source, is compatible with Okuma OSP and can also be integrated in confined spaces. *Handling weight depending on workpiece center of gravity

The LT series also becomes an efficient automation solution thanks to the SherpaLoader®. It is suitable for small batch sizes as well as for inserts, shafts, semi-finished products and castings. Robots weighing up to 73 kg can handle heavy parts. Unloading is possible when feeding with bar feeders. Retrofitting is carried out from a single source and is fully compatible with Okuma OSP.

With the SherpaLoader®, the Multus series becomes the ideal platform for complex turning and milling operations. It offers a high workpiece capacity in a very small space and is suitable for both small and large batch sizes. Thanks to the milling spindle, generous space and numerous tool stations, milled parts as well as turned parts can be inserted automatically - from cast parts and saw cuts to shafts and semi-finished products. Even standard Euro pallets can be used as material feeders. Machines without automation preparation can also be retrofitted. The systems are compatible with Fanuc and Siemens controllers and can be set up flexibly, even in confined spaces. Robots with a workpiece weight of up to 73 kg enable even heavy parts to be turned safely.

The SherpaLoader® M7 and SherpaLoader® M12 are ideal for Okuma milling machines that are used for Machining smaller parts. They speed up loading and increase efficiency for prototypes and small series.

The SherpaLoader® M25 and SherpaLoader® M50 models are designed for Okuma milling machines with medium workpiece sizes. They offer flexible automation that can be seamlessly integrated into existing production processes.

SherpaLoader® M88 and SherpaLoader® M225 are the right choice for Okuma milling machines that are used for Machining large and heavy parts. They guarantee maximum stability and enable 24/7 automation, even with demanding workpieces.

The SherpaLoader® turns the Okuma Genos M into a highly flexible production cell. Small and large workpieces can be fed automatically, an optional turning station enables backworking and several workpieces can be clamped simultaneously on the large machine table. None of the zero-point clamping is required, so the machine can be equipped with different clamping devices at any time - mechanical clamping devices are sufficient. The solution is suitable for both stackable and non-stackable workpieces. Machines without automation preparation can also be retrofitted. The systems are fully compatible with the Okuma robot interface and the OSP control system.

The SherpaLoader® is compatible with both New Okuma machines and existing systems. Machine tools have been equipped with bus interfaces for automation for over 15 years - the common standards Profibus, Profinet and EtherNet/IP are supported.

Machines without a bus interface can also be automated: MAFU-SHERPA connects them via M functions and potential-free contacts. This is done in compliance with directives and without expensive retrofitting by the machine manufacturer.

Retrofitting is carried out step by step and without complicated processes. After a short planning phase, the system is installed and put into operation. Commissioning is quick and easy, so that the Okuma machine continues to work productively without Lengthwise interruption.

The SpaceBox is a mobile storage device in Euro pallet dimensions (1,200 x 800 mm) with up to 10 pull-outs. It offers a total of 6 square meters of storage space and room for more than 1,500 small parts. Each pull-out can be removed individually and is secured during transport. With the MultiJob extension, each pull-out can be assigned its own NC program - ideal for flexible production on Okuma machines

The Table Trolleys offer a simple solution for flexible production on Okuma machines. Workpieces of different sizes can be provided quickly - perfect for prototypes, small batches or changing jobs. Standard size: 1,000 x 600 mm. Custom sizes available upon request.

Pallets are the right choice for large and heavy Parts. They enable reliable provision and consistent automation on Okuma machines, even for large quantities.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

All common Okuma machine types - from lathes and turn-mill centers to milling machines - can be automated with SherpaLoader®. Existing machines can also be easily retrofitted.

No. The SherpaLoader® systems work via standardized interfaces such as Profibus, Profinet or EtherNet/IP. It is not necessary to adapt the OSP control system.

Retrofitting is carried out in accordance with the guidelines and independently of the machine manufacturer. The Okuma warranty remains valid, as None of the controls or machine hardware are modified.

With SherpaLoader® automation, Okuma machines can produce around the clock. This increases capacity utilization and reduces unit costs - ideal for series production and flexible jobs.

Every Okuma machine has different requirements. In a personal consultation, we analyze which SherpaLoader® system is the best fit. This results in a customized automation concept.

Experience SherpaLoader® technology in action. A live demonstration will show how automation works on Okuma machines and what efficiency increases are possible. Make an appointment now: Telephone: +49 711 2525 744 - 0 E-mail: info@mafu-sherpa.com

An individual offer is prepared on the basis of the analysis. A profitability calculation clearly shows how quickly the investment in automation will pay for itself.

From the initial consultation to commissioning, MAFU-SHERPA accompanies the entire process. The implementation is simple and practical, so that the Okuma machine quickly automates production.

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us