Universal robot solution for all common HAAS machine types

With the SherpaLoader® camera-controlled robot solution, the automation of your HAAS machine can be easily retrofitted - for greater efficiency and less operating effort.

How it works

Automated turning of plastic gears on a HAAS ST-25Y - efficiently implemented with the SherpaLoader® T88. The workpieces are removed directly from Euro-Pallets, precisely aligned and reliably clamped. Automatic chuck cleaning ensures consistent quality with high spindle utilization. Ideal for series production in plastics technology. Watch the video here

The automation of sensitive plastic housings on a HAAS VF-3SS shows how gentle handling and high precision can be combined. The SherpaLoader® M25 picks up the workpieces from the SpaceBox with TPE grippers, cleans them automatically and transfers them ready for clamping. The system enables economical production even with varying geometries and small batch sizes. Watch the video here

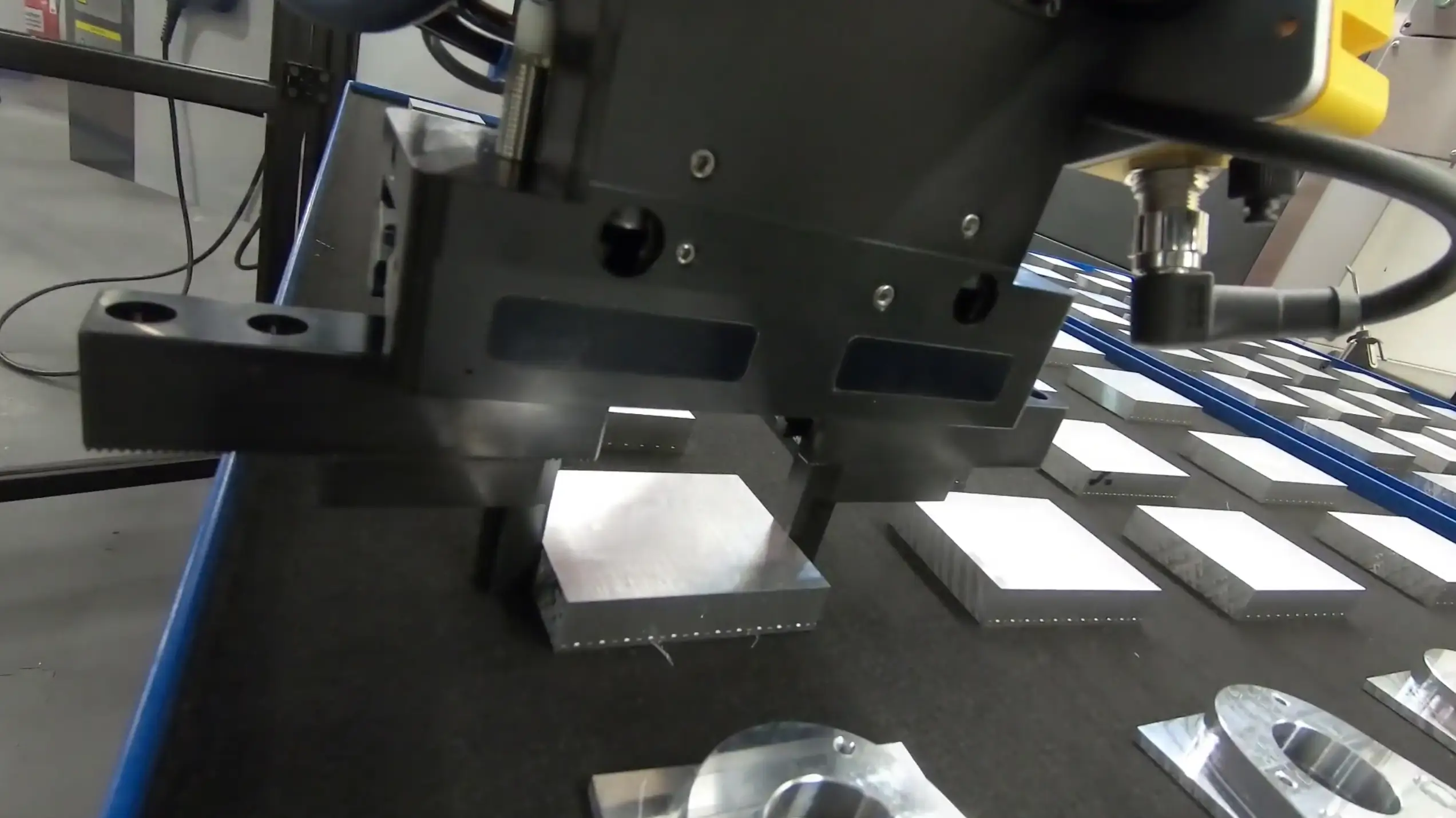

The 5-axis Machining of sawn cuboids on a HAAS UMC 750 is automated by the SherpaLoader®. Workpieces are provided via Table Trolleys, recognized by camera and positioned precisely. The solution is particularly suitable for complex geometries and medium-sized series in prototype construction or single part production. Watch the video here

The robot solutions are compatible with all HAAS machine types - from compact lathes to large-format 5-axis machining centers. Thanks to the modular design and flexible workpiece recognition, a wide range of production requirements can be automated. Most older machines without robot preparation can also be easily retrofitted.

The automatic workpiece feed keeps the spindle active - even at night and at weekends. The robot cell takes care of loading and unloading autonomously, minimizing non-productive times and significantly increasing machine uptime.

Automation relieves the strain on operating personnel and reduces the need for manual intervention. This means that stable production processes can be achieved even when there is a shortage of skilled workers - with higher output and lower costs per Part.

Every movement is carried out reproducibly and with consistent precision. Workpieces are precisely positioned, cleaned and clamped - regardless of shift operation or personnel changes. The result: consistent quality and fewer rejects.

Automation remains economical even with varying batch sizes and frequent workpiece changes. The fast changeover and flexible material supply enable efficient series production without long set-up times

The integrated 3D laser Vision System detects workpieces autonomously and accurately - regardless of shape, material or position. Intelligent image processing enables reliable identification even with irregular geometries or varying surfaces. This automates loading efficiently and error-free.

Changing workpieces does not require any complex programming or mechanical adjustments. The robot cell adapts flexibly to new parts - with a changeover time of less than five minutes. Ideal for small series, changing jobs and agile manufacturing processes.

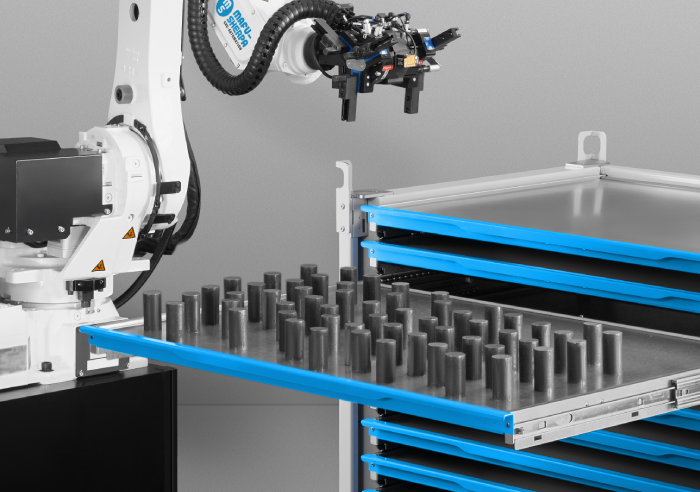

Whether sensitive plastic parts, sawn cuboids or stackable metal blanks - the material is supplied via SpaceBox, Table Trolleys or Euro Pallets. The robot cell automatically recognizes the position of the workpieces and picks them up ready for clamping. This keeps production flexible and scalable.

The robot cell is controlled via an intuitive user interface - without any programming knowledge. Predefined sequences and visual assistance functions enable Faster familiarization and safe operation, even for users without robotics experience.

The SherpaLoader® M7 and SherpaLoader® M25 models are suitable for the automation of light and medium-weight workpieces. The robot cells handle sensitive parts with precision, enable quick workpiece changes and ensure consistent processing quality - ideal for plastic housings, aluminum parts and complex milled parts.

The SherpaLoader® M50 or SherpaLoader® M88 offers the right solution for heavy workpieces or large-volume series. The robust design and high load capacity enable the automation of steel parts, castings or solid milled bodies. Process reliability is guaranteed even with high quantities - with maximum spindle utilization and minimum operating effort.

The SherpaLoader® T7 and SherpaLoader® T25 models offer a compact and powerful solution for the automated machining of chuck parts and short shafts on HAAS ST lathes. The robot cells perform precise loading and unloading directly from the Raw Material Staging, clean the chuck automatically and ensure consistent process quality - even with high quantities.

The SherpaLoader® T50 and SherpaLoader® T88 are used for the automation of long or heavy turned parts. The robust design and high load capacity enable the safe handling of complex workpieces - including automatic alignment and clamping. The solution is particularly suitable for series production in metalworking and for applications with high material weights.

The robot cells are fully compatible with the requirements of 5-axis machining centers such as the HAAS UMC series. Workpieces with complex geometries are recognized and precisely positioned with camera support. The automation supports simultaneous machining processes and ensures maximum spindle utilization with high repeat accuracy.

For the automation of medium-heavy workpieces on HAAS UMC machines, the SherpaLoader® M25 and SherpaLoader® M50 models offer a balanced combination of payload, speed and precision. The robot cells are ideal for applications in tool and mold making as well as for Machining technical plastics and aluminum parts.

The SherpaLoader® M88 is used for particularly heavy workpieces or complex parts. The powerful robot cell can handle high masses and demanding clamping processes - even with sawn cuboids or rotationally symmetrical parts. The solution enables stable and economical production in demanding 5-axis processes.

A universal interface enables direct connection without additional hardware or software adaptations. This makes retrofitting efficient and cost-saving.

Even machines without factory robot preparation can be automated without any problems. The robot cell takes over all relevant functions independently and integrates seamlessly into existing processes. No mechanical or control system conversion is required.

The retrofit is available for all common HAAS series - from VF machining centers to ST lathes and UMC universal centers. The robot cell is individually adapted to the respective machine configuration and ensures stable, reliable automation.

The path to automated production begins with an individual needs analysis. This is followed by technical planning, mechanical integration and commissioning - including training and production support. This turns retrofitting into a sustainable competitive advantage. The fastest commissioning time was 3 days, including staff training.

The robot cells are fully compatible with the requirements of 5-axis machining centers such as the HAAS UMC series. Workpieces with complex geometries are recognized and precisely positioned with camera support. The automation supports simultaneous machining processes and ensures maximum spindle utilization with high repeat accuracy.

For the automation of medium-heavy workpieces on HAAS UMC machines, the SherpaLoader® M25 and M50 models offer a balanced combination of payload, speed and precision. The robot cells are ideal for applications in tool and mold making as well as for Machining technical plastics and aluminum parts.

Machines without an existing bus interface are automated via M functions and potential-free contacts. The SherpaLoader® comes with all the necessary components and makes your existing machines fit for the future.

The SherpaLoader® M88 is used for particularly heavy workpieces or complex parts. The powerful robot cell can handle high masses and demanding clamping processes - even with sawn cuboids or rotationally symmetrical parts. The solution enables stable and economical production in demanding 5-axis processes.

A universal interface enables direct connection without additional hardware or software adaptations. This makes retrofitting efficient and cost-saving.

Even machines without factory robot preparation can be automated without any problems. The robot cell takes over all relevant functions independently and integrates seamlessly into existing processes. No mechanical or control system conversion is required.

The retrofit is available for all common HAAS series - from VF machining centers to ST lathes and UMC universal centers. The robot cell is individually adapted to the respective machine configuration and ensures stable, reliable automation.

The path to automated production begins with an individual needs analysis. This is followed by technical planning, mechanical integration and commissioning - including training and production support. This turns retrofitting into a sustainable competitive advantage. The fastest commissioning time was 3 days, including staff training.

All standard HAAS CNC machines can be retrofitted - regardless of the year of manufacture or equipment. The robot cells are compatible with VF machining centers, ST lathes, UMC universal centers and Next series. Machines without factory robot preparation can also be automated.

Retrofitting is carried out via an external interface and does not affect the machine functions. As a rule, the manufacturer's warranty is retained, provided None of the controls or mechanics are extensively modified.

In many cases, the robot cell can be integrated without a Lengthwise production stop. The mechanical connection and commissioning are planned in such a way that ongoing processes are affected as little as possible. Precise coordination takes place as part of the project planning.

The fastest commissioning was completed in just 3 days, including training.

The robot cells cover a wide spectrum - from small plastic parts to heavy metal blanks. The selection of the right SherpaLoader® depends on the geometry, weight and series size.

A live demonstration will show how the robot cell works - with real workpieces and under real production conditions. The presentation includes workpiece detection, loading, clamping and unloading. This provides a clear picture of the automation potential in your own company.

Arrange a presentation now:

Call us - +49 711 2525 744 - 0

Write to us - info@mafu-sherpa.com

From the initial idea to productive manufacturing: Project support includes requirements analysis, technical planning, mechanical integration and training. Each step is individually coordinated - with the aim of implementing a stable, economical and future-proof automation solution for your HAAS machine.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us