Easy to set up

- even with daily changing articles

TROST operates two SherpaLoaders® in contract manufacturing for 5-axis machining

Alexander Trost founded the company in Rahden in 2006 with a vertical machining center. Today, the company manufactures on seven modern CNC machining centers with ten qualified employees on an area of 1,300 m².

Easier automation with the SherpaLoader®

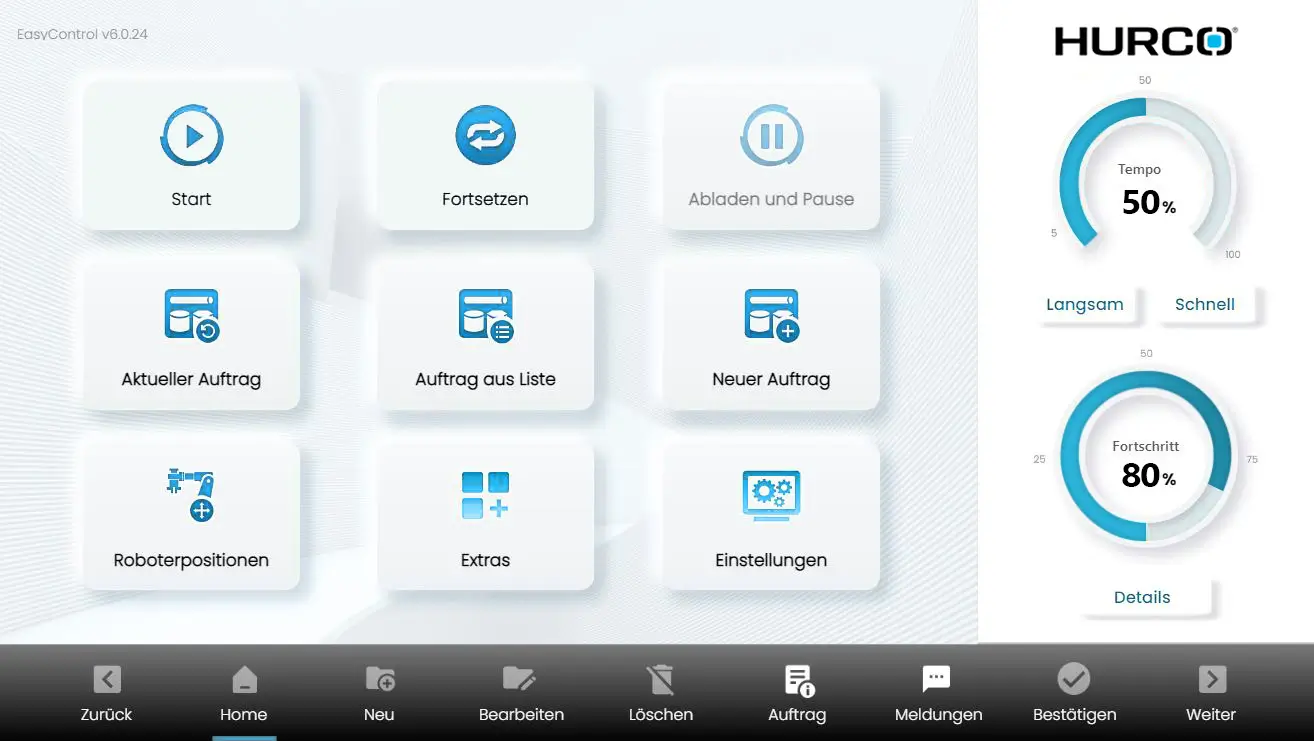

Performing manufacturing tasks as simply as possible is one of the supreme disciplines of machining. Automation can help here, especially if it makes simplicity its premise. Together with MAFU-SHERPA CNC Automation GmbH, HURCO shows how camera-controlled robotics increases productivity, improves efficiency and makes manufacturing workplaces more attractive.

Efficient production of small and medium-sized series

“Our daily challenge is to remain competitive. Because it’s getting tougher and tougher,” emphasizes Alexander Trost, Managing Director of TROST Zerspanungstechnik GmbH & Co. KG from Rahden. “Our primary goal is to ensure trouble-free operation of the machines, while at the same time relieving the strain on the operators.” TROST manufactures precision components for machine and special machine construction, typically small and medium-sized series. The company has relied on reliable 3- and 5-axis machining centers from HURCO for many years. The automation of a HURCO VMX 30Ui with the SherpaLoader® was implemented to reduce set-up times and relieve personnel.

Automated 5-axis Machining at TROST

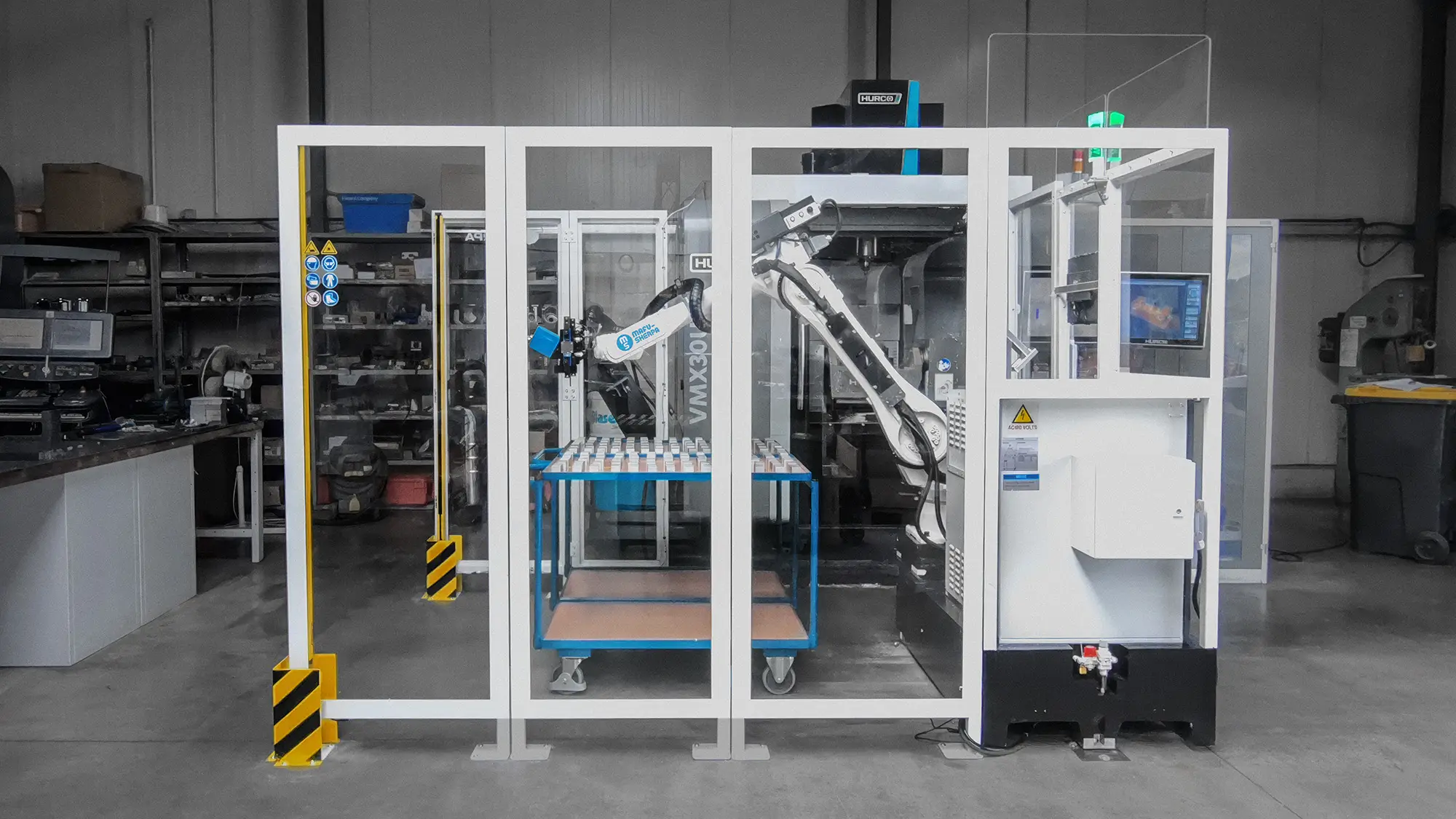

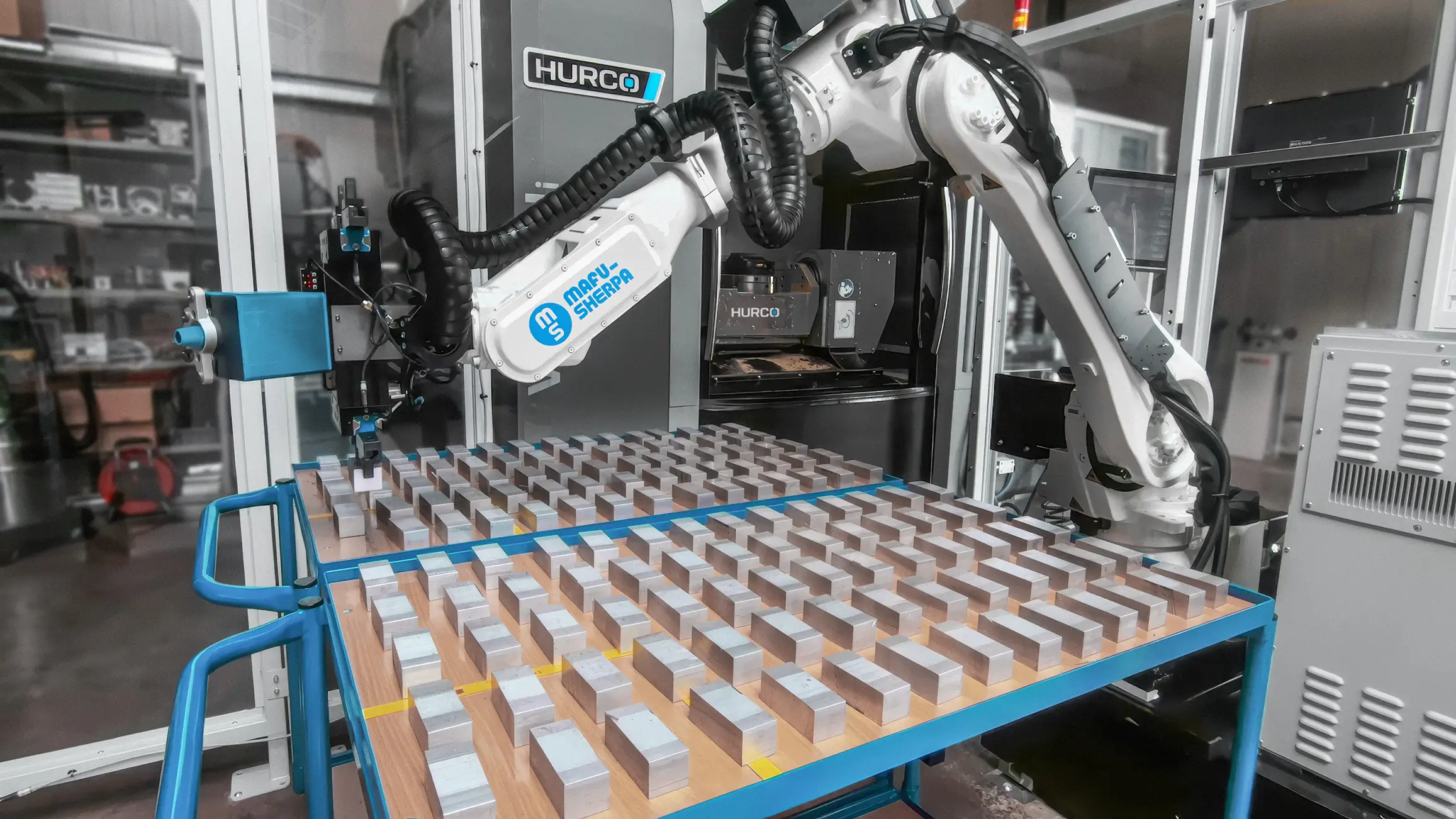

At TROST, a SherpaLoader® has been handling all workpieces since 2021, from material provision to the finished part. Two Table Trolleys serve as Raw Material Staging. A 3D camera system on the robot recognizes prepared blanks regardless of their position, meaning that no matrices or fixed stops are required. The robot precisely aligns the blank, automatically clamps it in the vice of the HURCO VMX 30Ui and starts Machining. After machining, the SherpaLoader® M20 cleans the workpiece with compressed air, removes it and inserts the next blank directly. In this way, loading and unloading processes run synchronously – for maximum spindle running time and process reliability. During the day, we have reduced the number of staff, and in the evening we can continue production unmanned,” reports Trost. “The combination of HURCO machine and Sherpa automation has proven itself, and since 2024 another SherpaLoader® has been loading a VMX42 SRti in production – our key to stable productivity.”

Maximum flexibility through camera control

Whether milling or turning, the SherpaLoader® systems have a modular design and cover 6-axis robots of 7 to 225 kg. Its 3D Vision System and laser system automatically recognizes parts, adapts to new geometries and enables changeovers in under five minutes. Workpieces can be provided flexibly and in a space-saving manner using Table Trolleys, Pallets or the SpaceBox pull-out system. This camera-supported intelligence ensures robust handling, less manual intervention and consistent machine availability – perfect for small and medium-sized series.