Universal robot solution for all GF machine types

Would you like to automate the manufacturing process of your GF machine and reliably maximize the productivity of your production? Whether an existing system or a new acquisition, you can automate your Georg Fischer machines efficiently and reliably with robotics solutions from MAFU-SHERPA. Easily adapt your production process to changing production conditions. The integrated camera-based detection system enables the detection and processing of a wide variety of workpieces. Set-up times are significantly reduced! With almost fully automated component handling, you can ensure consistently high production quality while reducing manual intervention. This allows you to increase the productivity of your production and utilize the full potential of your GF machines!

How it worksThe automated workpiece feed ensures that your GF machine is continuously supplied with raw parts. The camera-based recognition system identifies the workpieces regardless of their position and transfers them precisely to the process. Non-productive times are reduced and the spindle time of the GF machine is optimally utilized!

The automation systems of MAFU-SHERPA take care of material handling, clamping and component removal on your GF machine. The flexible Raw Material Staging systems enable autonomous operation over several hours. Manual labor and personnel costs are reduced!

Automating your production process with robot systems from MAFU-SHERPA enables end-to-end automated material handling. From material provision to clamping in your GF machine - our automation solutions adapt to your process! Component quality remains constant throughout the entire production process and deviations due to manual intervention are avoided.

The automation of your GF machine enables cost-efficient Machining of small and medium-sized series. Thanks to the camera-based recognition system, raw parts are identified quickly and regardless of their position. Set-up times are significantly reduced! This means that even changing batch sizes can be implemented economically without compromising process stability or machining quality.

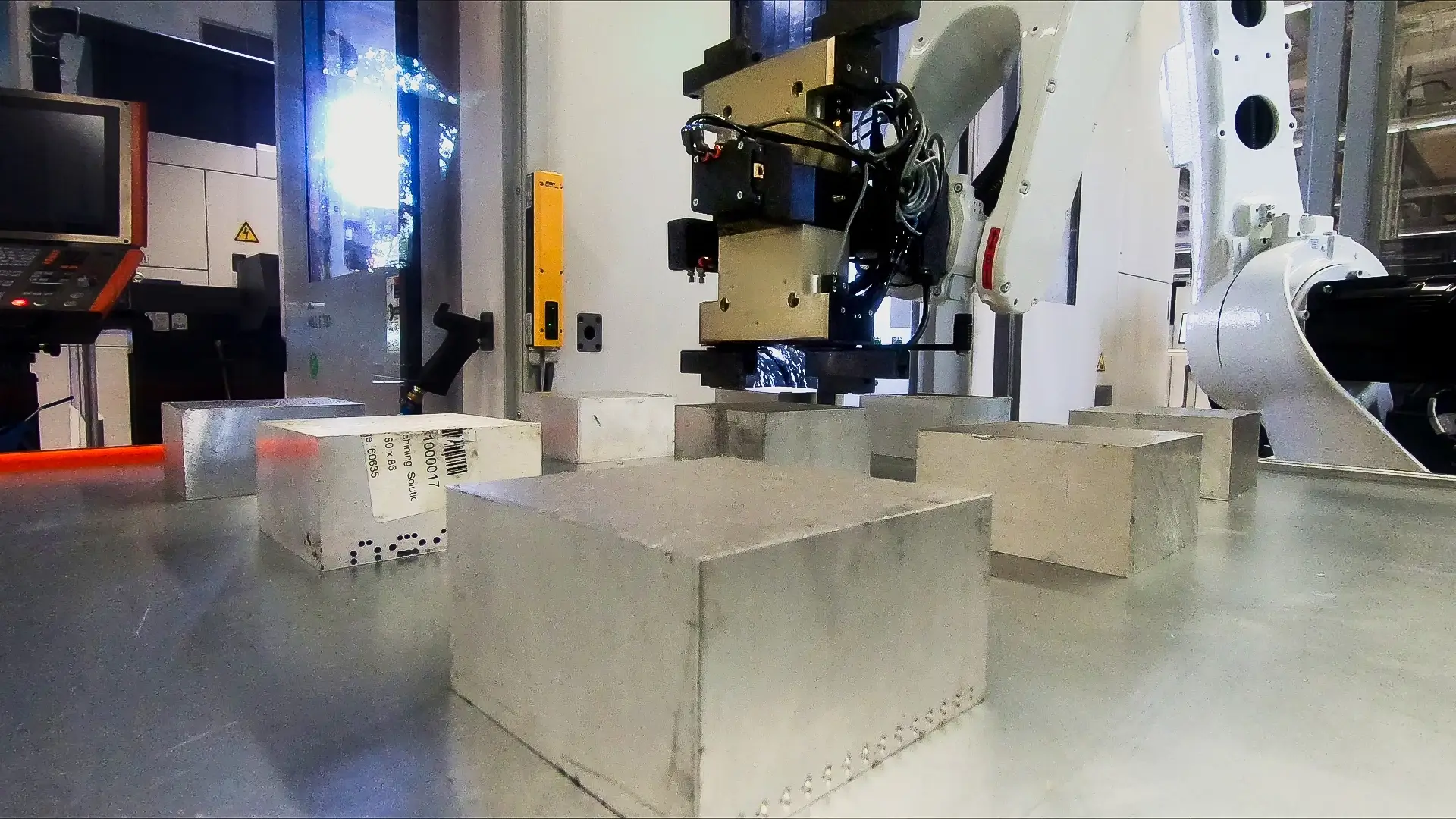

The integrated 3D camera laser system recognizes blanks regardless of their position. This ensures precise pre-alignment and clamping of the workpieces in your GF machine. Time-consuming manual clamping is no longer necessary and varying workpiece positions are avoided. The result is short non-productive times with consistently high process reliability in your production.

The automation of your GF machine reduces set-up times to a minimum. Workpieces can be changed in less than five minutes. Frequent changeovers remain economical. This creates flexibility for changing jobs and increases your machine availability.

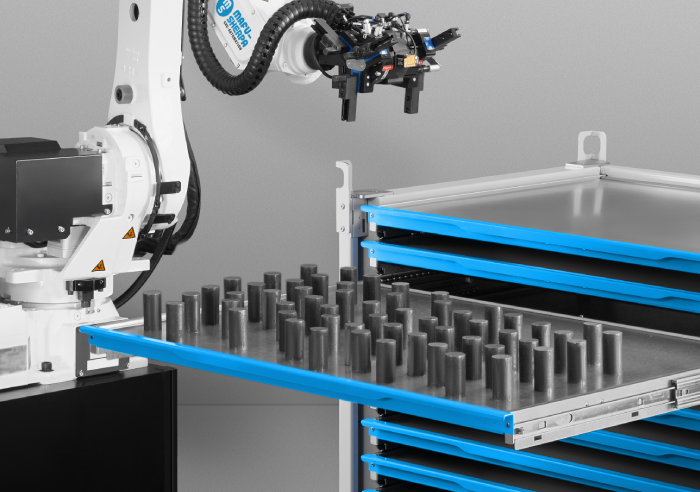

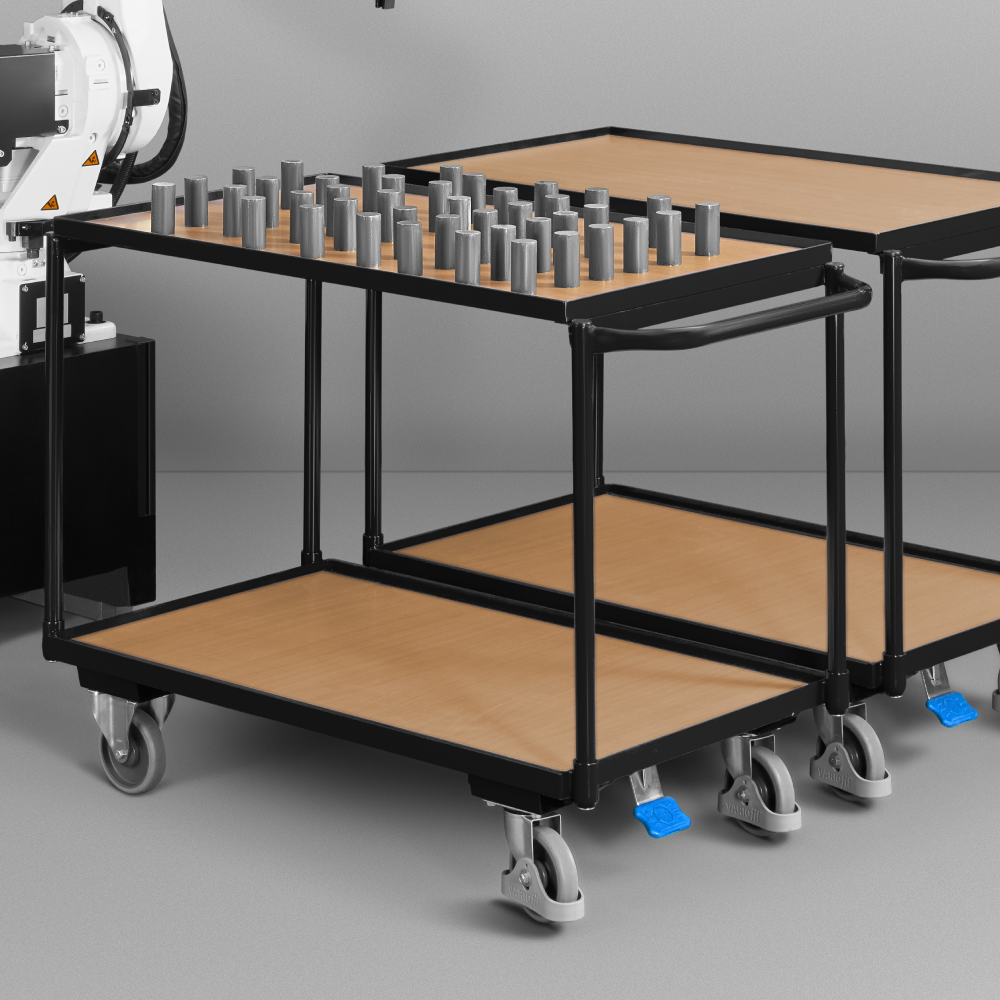

Several material supply systems are available for the automation of your GF machine. Whether via SpaceBox, Table Trolleys or Pallets - material supply is flexible and adaptable to different production environments. This allows workpieces to be efficiently stocked and continuously fed into the process.

You can conveniently control the automation on your GF machine via a 17" touch display with intuitive dialog guidance. Time-consuming programming work is completely eliminated, so you can set up new workpieces in no time at all. You can operate the system safely and efficiently even without in-depth prior knowledge - and make full use of the automation of your production!

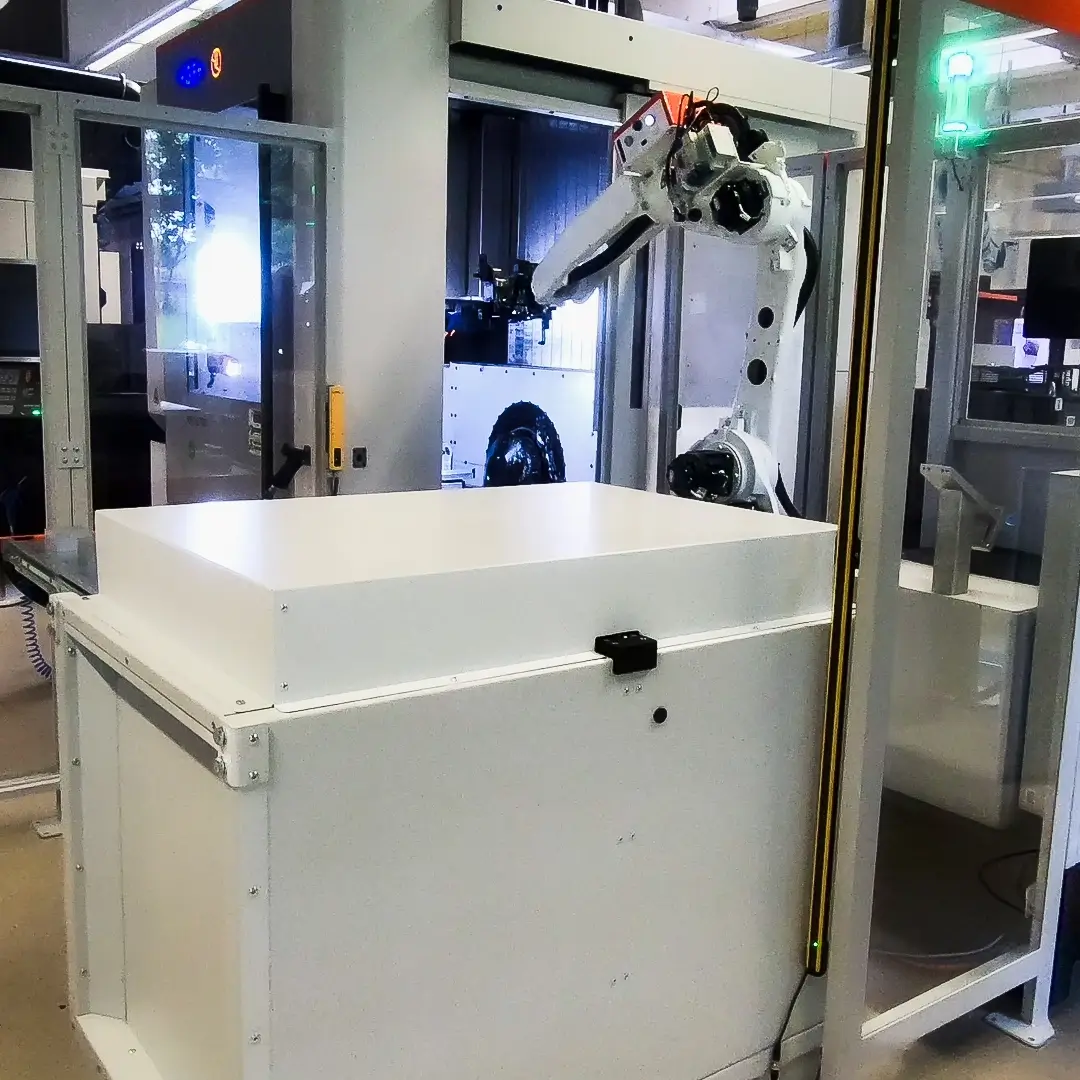

The implementation of the SherpaLoader® M25 in the production process of a GF Machining MILL E 700 U enables complete automation. The camera-based recognition system reliably identifies the workpieces, while the SpaceBox ensures orderly material provision. This makes the manufacturing process efficient and reliable.

Learn more

Automating your Mikron HSM machine ensures reproducible precision when Machining the finest geometries. The automation systems from MAFU-SHERPA support 5-axis Machining through constant workpiece feeding and ensure that the performance of your HSM system is utilized without interruption.

The SherpaLoader® M7 and SherpaLoader® M25 models offer optimum conditions for Machining small to medium-sized workpieces. They reliably perform automated handling and enable economical series production with reduced non-productive times.

When Machining large and heavy workpieces, the SherpaLoader® M50 and SherpaLoader® M88 models offer the necessary load capacity and stability. This ensures a safe material flow even with complex Parts.

By automating your GF machine with systems from MAFU-SHERPA, you can ensure precise and reliable workpiece feeding. Our automation solutions ensure repeatable positioning so that even the smallest tolerances are maintained. Your machine always works with maximum precision!

In the automated production process of your AgieCharmilles FORM with systems from MAFU-SHERPA, the robot takes over the automatic electrode handling. Thanks to the gentle transport concept of the automation systems, workpieces and electrodes are moved carefully. Damage is avoided and the machine is continuously and optimally supplied with raw parts.

With the automation systems of MAFU-SHERPA, you can reliably automate the workpiece feed in your AgieCharmilles CUT machine. The integrated camera-based recognition system precisely identifies raw parts. Non-productive times are significantly reduced and consistent process quality is ensured. Thanks to the short set-up time, economical production is guaranteed even with frequently changing workpieces.

Existing AgieCharmilles production cells can also be easily automated with MAFU-SHERPA systems. Standardized interfaces and flexible material provision ensure a continuous production flow. Your existing processes do not need to be adapted! This allows you to integrate the robot technology efficiently and economically into your existing production.

With the automation systems of MAFU-SHERPA, you can easily automate your GF machines. The compatibility of our systems with the Heidenhain control system of your GF machine enables fast commissioning and significantly reduces the effort required for individual adaptations.

With the automation systems of MAFU-SHERPA you can subsequently automate your GF machines. None interventions or modifications to the manufacturer's design are necessary. This means that your existing GF machine can be efficiently integrated into automated processes and used economically.

Would you like to automate your existing production economically? None of your problems! Even older machines from the Mikron and AgieCharmilles series can be easily automated with systems from MAFU-SHERPA. By using robot solutions, you benefit from shorter non-productive times, reduced personnel costs and more efficient utilization of your existing machines.

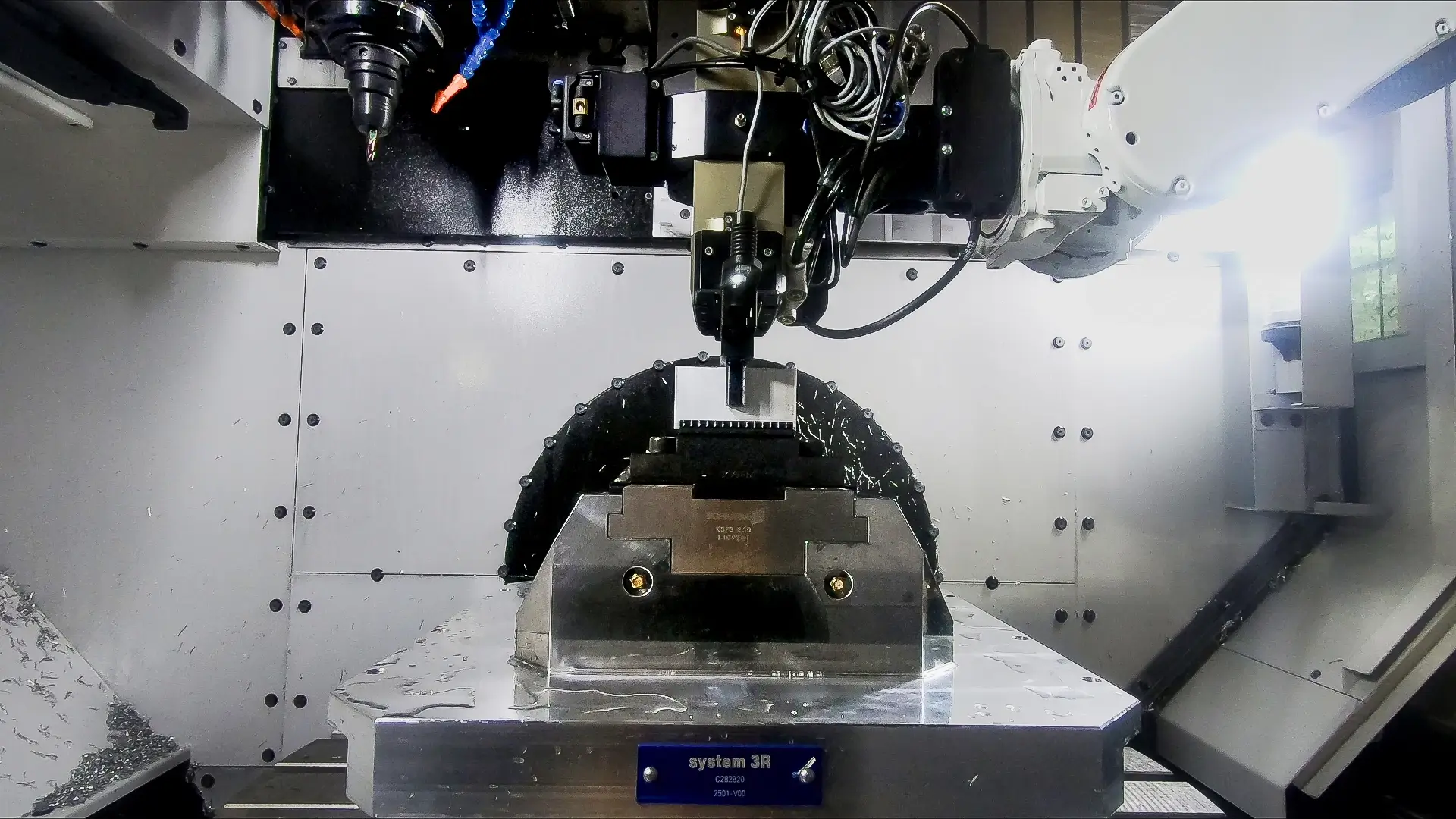

The automation systems of MAFU-SHERPA are fully compatible with System 3R. This compatibility allows you to maximize spindle time by significantly reducing set-up times! This increases the efficiency of your production while maintaining precision and process reliability.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

With the automation systems of MAFU-SHERPA, you can flexibly integrate your GF machines into existing processes. In contrast to manufacturer-specific automation systems, you are not limited to one solution. Your production is designed to be independent and scalable in the long term.

The camera-based recognition system from MAFU-SHERPA offers you maximum flexibility in material provision. In contrast to purely mechanical systems, the robots detect raw parts regardless of their position, thereby reducing set-up times and material provision requirements. Process reliability and component quality are maximized!

Do you want to automate your existing production economically without purchasing expensive new systems? With the automation solutions of MAFU-SHERPA, you can easily retrofit your existing GF machines. This allows you to increase the productivity of your existing systems and ensure cost-effective production without unnecessary replacement investments.

MAFU-SHERPA systems are universally compatible and can be integrated into a wide range of GF machines. This allows you to avoid the limitations of exclusive manufacturer solutions and benefit from flexible, future-proof automation.

Efficient material supply is crucial for a smooth automated production process. Different material storage concepts enable a continuous supply to your GF machines and thus contribute to process stability and high machine utilization.

The SpaceBox enables structured and space-saving material provision for micron machines. Thanks to the defined separation of individual workpieces and compatibility with the MAFU-SHERPA systems, precise component feeding is achieved, which is particularly suitable for high-precision micron machining.

For large and heavy workpieces in AgieCharmilles machines, pallet handling offers a stable solution for material provision. The workpieces are provided directly via a Pallet. Massive parts can be handled safely and reproducibly. The automation systems from MAFU-SHERPA ensure a controlled transfer and support precise manufacturing processes under high loads.

Table Trolleys can be used to flexibly provide smaller workpieces and prototypes for research and development purposes. The MAFU-SHERPA systems support rapid adjustment of the material supply and thus ensure efficient processes in variable production environments. This makes them ideal for companies that test frequently changing component geometries or produce small batches.

The automation systems of MAFU-SHERPA can be seamlessly integrated into existing GF production environments. Thanks to full System 3R compatibility, existing interfaces can continue to be used. No conversion is necessary. This significantly reduces set-up times while maintaining the flexibility and scalability of your production.

All GF machine models, including the Mikron and AgieCharmilles series, can be equipped with automation systems from MAFU-SHERPA. The solutions are universally designed and can be used regardless of the year of manufacture or machine size.

No, retrofitting with MAFU-SHERPA systems does not affect the GF machine warranty. Automation is carried out without any intervention in the machine control system or manufacturer-specific modifications.

Yes, the MAFU-SHERPA systems do not require any factory automation preparation on the part of GF. The connection is made via universal interfaces and can also be easily implemented in existing systems.

Compared to the System 3R TRANSFORMER, the MAFU-SHERPA systems offer increased flexibility in material provision, shorter set-up times and universal applicability for all GF machines. In addition, the integrated camera-based recognition system ensures precise component identification and repeatable clamping. Process reliability is increased!

Efficient material supply is crucial for a smooth automated production process. Different material storage concepts enable a continuous supply to your GF machines and thus contribute to process stability and high machine utilization.

The SpaceBox enables structured and space-saving material provision for micron machines. Thanks to the defined separation of individual workpieces and compatibility with the MAFU-SHERPA systems, precise component feeding is achieved, which is particularly suitable for high-precision micron machining.

For large and heavy workpieces in AgieCharmilles machines, pallet handling offers a stable solution for material provision. The workpieces are provided directly via a Pallet. Massive parts can be handled safely and reproducibly. The automation systems from MAFU-SHERPA ensure a controlled transfer and support precise manufacturing processes under high loads.

Table Trolleys can be used to flexibly provide smaller workpieces and prototypes for research and development purposes. The MAFU-SHERPA systems support rapid adjustment of the material supply and thus ensure efficient processes in variable production environments. This makes them ideal for companies that test frequently changing component geometries or produce small batches.

The automation systems of MAFU-SHERPA can be seamlessly integrated into existing GF production environments. Thanks to full System 3R compatibility, existing interfaces can continue to be used. No conversion is necessary. This significantly reduces set-up times while maintaining the flexibility and scalability of your production.

Expand your production process with additional modules that cover every Detail.

Our experts examine your GF machines and production processes in detail in order to develop tailor-made automation solutions. We take into account component geometries, batch sizes and existing production environments.

On request, we can demonstrate the automation directly on your GF machine. You can experience the precise workpiece handling, camera-based detection and efficient process sequences live. Discover how automation can be seamlessly integrated into your production and support your production processes.

We create a transparent cost comparison between retrofitting with MAFU-SHERPA systems and GF original solutions. This allows you to identify potential savings in investment, set-up times and personnel costs.

Our advice is completely neutral and independent of GF or other manufacturers. You receive recommendations that are exclusively geared towards your production, efficiency and cost-effectiveness. This allows you to make well-founded decisions without being restricted by manufacturer-specific specifications.

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us