Universal robot solution for all Mikron machine types

MAFU-SHERPA offers an intelligent robot solution for the automated loading of Mikron machining centers. With camera-controlled workpiece recognition and flexible material provision, your production becomes easier, faster and more economical. Customers receive ready-to-use automation that efficiently complements existing machines - regardless of model or year of manufacture. The solution increases productivity, reduces costs and makes your production fit for economical 24/7 operation.

Non-binding adviceMAFU-SHERPA automation significantly increases the spindle time of your Mikron CNC machine. The SherpaLoader automatically feeds and removes the workpieces so that your machine works without interruption - even at night and at weekends. Autonomous workpiece feeding eliminates the need for manual loading and the machine remains in continuous operation. This increases productivity and ensures optimum utilization of your production capacities.

Mikron machines used in the medical technology and watchmaking industries in particular require maximum precision. The robot solution guarantees repeatable handling of the workpieces. The camera-based system recognizes and positions each part exactly, regardless of shape or position. This means that the precision standard remains constant even with the smallest tolerances, and your production meets the strict quality requirements of these industries at all times.

With Mikron CNC automation from MAFU-SHERPA, you can also produce small and medium-sized series economically. The flexible robot solution enables fast changeovers and short set-up times, so that even changing jobs and smaller batch sizes can be automated profitably. The system adapts to your production requirements and ensures efficient production - regardless of the quantity or component variance.

Robot automation ensures the consistently high quality of your parts. Camera-supported detection and precise handling ensure that workpieces are always positioned and clamped exactly. This minimizes sources of error and ensures consistent quality - even with challenging geometries and the tightest tolerances. Your production remains stable and waste is sustainably reduced.

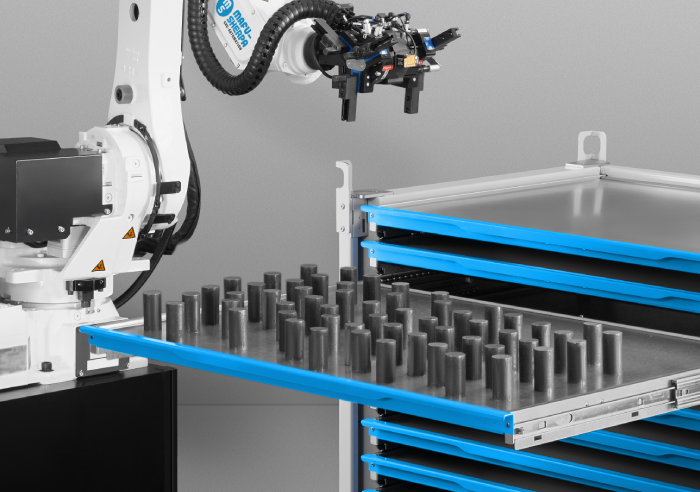

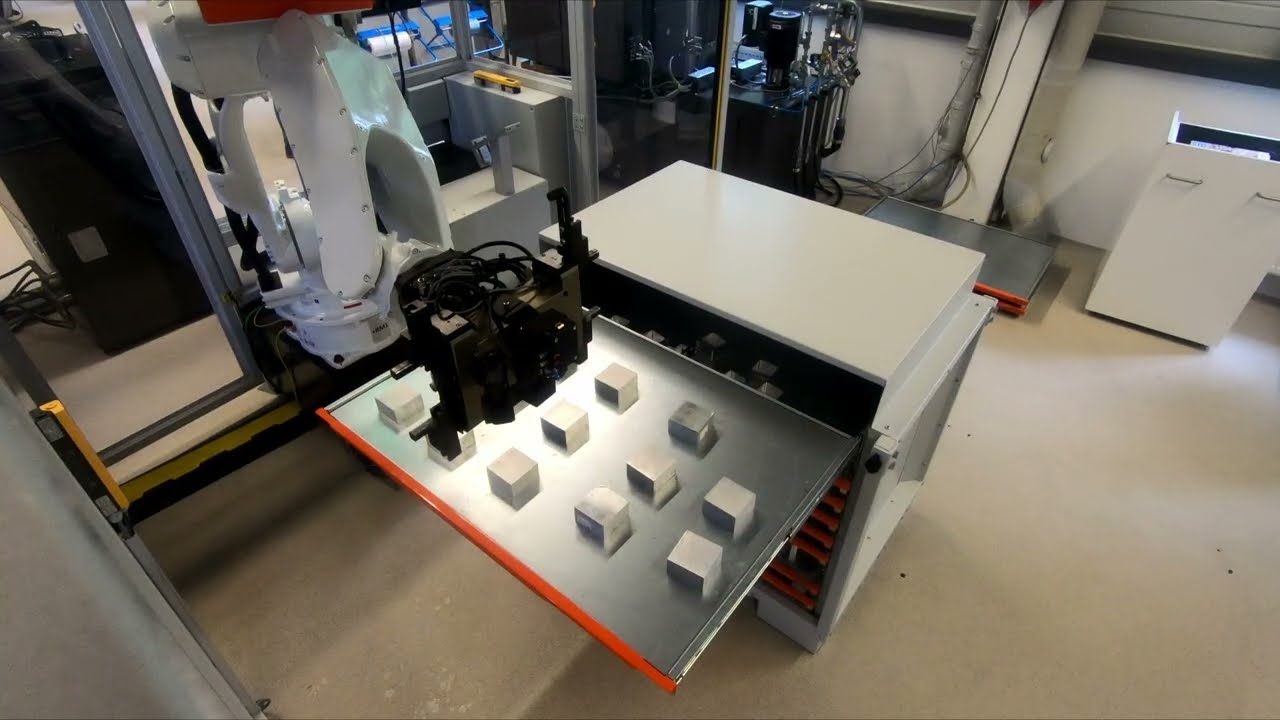

At the heart of the automation is the 3D laser Vision System. It recognizes workpieces regardless of their position or shape on Table Trolleys, Pallets or in the SpaceBox. This eliminates the need for time-consuming set-up of mechanical devices. Intelligent image recognition ensures maximum precision when picking up workpieces and guarantees reliable, repeatable transfer to your Mikron CNC machine.

With the robot solution, you can switch to a new workpiece in less than five minutes. The changeover is limited to adapting the gripper fingers - there is no need for complex mechanical conversions. This enables flexible production, even with frequently changing jobs or small batch sizes. Your Mikron machine remains productive and downtimes are reduced to a minimum.

Materials are supplied flexibly via SpaceBox, Table Trolleys or Pallets. You choose the right system depending on the component size and quantity. The SpaceBox offers space for over 1,500 small parts, Table Trolleys are suitable for prototypes and small batches, and Pallets are ideal for heavy or large workpieces. The camera-based system recognizes the parts regardless of their position and ensures a smooth material flow.

Operation is via an intuitive dialog control with touch display. None of you need any special programming knowledge for Heidenhain or robot controls. New Jobs are simply set up using graphical input masks. This means that even employees without robotics experience can operate the automation safely and efficiently.

For small and light workpieces on Mikron machines, the SherpaLoader® M7 and SherpaLoader® M12 is the ideal choice. They handle parts weighing up to 4 kg (M7)* or 8 kg (M12)* and cover a size range: from 10 x 10 x 10 mm to 150 x 150 x 150 mm. The compact design allows them to be used even where space is limited. Ideal for precision parts in medical technology or precision mechanics.

For medium-heavy workpieces, MAFU-SHERPA offers the models SherpaLoader® M25 and M50. The M25 is designed for parts up to 18 kg* and 200 x 200 x 200 mm, the M50 for up to 38 kg* and 300 x 300 x 300 mm. Both systems can be used flexibly and are suitable for the demanding precision parts that are typical of Mikron applications. The robust design ensures reliable processes even with higher quantities.

For large and heavy parts on Mikron machines, the SherpaLoader® M88 is the right solution. It can handle workpieces up to 73 kg* and 300 x 300 x 300 mm. The high load capacity and stable handling make it ideal for demanding applications in mechanical engineering or for large series. Even particularly heavy and project-specific components can be handled safely and precisely with the SherpaLoader® M225 can be automated. *Handling weight depending on workpiece center of gravity

MAFU-SHERPA automation is compatible with all common Heidenhain TNC controls. The connection is made via universal interfaces such as Profibus, Profinet or EtherNet/IP.

Your Mikron machine can be retrofitted without any intervention in the machine control system or modifications by the manufacturer. The automation is connected externally and works independently of the original control system. This protects your investment and avoids warranty restrictions. The installation can be implemented quickly and without long downtimes.

Even older machines without a bus interface can be easily integrated - via M functions and potential-free contacts. This allows you to automate your existing machines easily and safely. All the necessary functions, including door drive and clamping device actuation, can be retrofitted. This means that existing systems also benefit from modern automation without the need for expensive new machines or manufacturer-specific adaptations.

MAFU-SHERPA provides you with a flexible and independent alternative to manufacturer-specific automation systems. The solution can be used universally, grows with your requirements and can be adapted to changing production conditions. You remain independent of exclusive manufacturer solutions and benefit from future-proof automation of your Mikron machines.

With automation for your Mikron, you can produce around the clock - even without staff. Automation enables unmanned shifts in the evening, at night and at weekends. This allows you to significantly increase the spindle time of your Mikron machine and make optimum use of your production capacities. Productivity increases and you can process more jobs in less time.

Automation reduces your personnel costs and increases your production capacity at the same time. Automation eliminates monotonous and physically demanding tasks. Your employees can concentrate on value-adding tasks while the machine produces autonomously. The investment usually pays for itself within a short time and ensures sustainable competitive advantages.

The automation of a Mikron HEM 500 U shows how much the spindle time can be increased with a SherpaLoader®. The machine was not originally prepared for automation, but with the robot solution it could be retrofitted without any intervention by the manufacturer. Since then, loading has been stable and has enabled significantly longer running times - even at night and at weekends. The effective spindle time has increased from 6 to over 20 hours per day, which has massively increased production capacity. The solution makes it possible to produce both small and large series economically and to make optimum use of the existing machine. You can find the full Customer Stories here.

The automation of a GF Machining Mill E 700 U with the SherpaLoader® M25 demonstrates the seamless integration into the Mikron/GF infrastructure. Material is supplied via the SpaceBox, and the camera-based system recognizes the workpieces regardless of their position. The synchronized processes ensure consistent component quality and maximum machine availability. Older models also benefit from this efficient automation solution. You can find more information here.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

In principle, all standard Mikron machines can be automated. The solution is universally designed and can be used regardless of the year of manufacture or machine size. Older models without automation preparation can also be retrofitted without any problems.

Retrofitting is carried out without interfering with the machine control system or making manufacturer-specific modifications. The warranty of your Mikron/GF system generally remains unaffected, as None of the original technology is modified. Each project is individually documented and coordinated.

Yes, the solution does not require any factory automation preparation. The connection is made via universal interfaces and can also be implemented in existing systems without special preparation. This means you benefit from modern automation, regardless of the age of your machine.

Integration is quick and easy. A complete installation with training was possible in just three days. The intuitive dialog control makes it easy to get started, so that the operating personnel quickly master the new process and immediately benefit from the automation.

Stable system operation requires reliable service and Faster support. The service concept covers regular maintenance, precise fault diagnosis and targeted optimization to ensure that the automation remains efficient in the long term. This ensures that production remains reliable, plannable and at a high level of quality at all times.

Every production environment is unique. The experts of MAFU-SHERPA analyze your specific Mikron automation requirements as part of a personal consultation. Together, they will develop a customized automation concept that is precisely tailored to your Mikron machine and your production goals. This gives you a solution that optimally supports your processes and sustainably increases your competitiveness.

See the advantages of the robot solution for yourself in a live demonstration. You will experience camera-supported part recognition, fast changeover and simple operation directly on an automated Mikron machine. Make an appointment and discover how you can make your production future-proof with modern robot automation.

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us