Advantages of robot automation for HURCO machining centers

The robot systems from MAFU-SHERPA make your HURCO production more productive, more flexible and more economical - from single part production to series production.

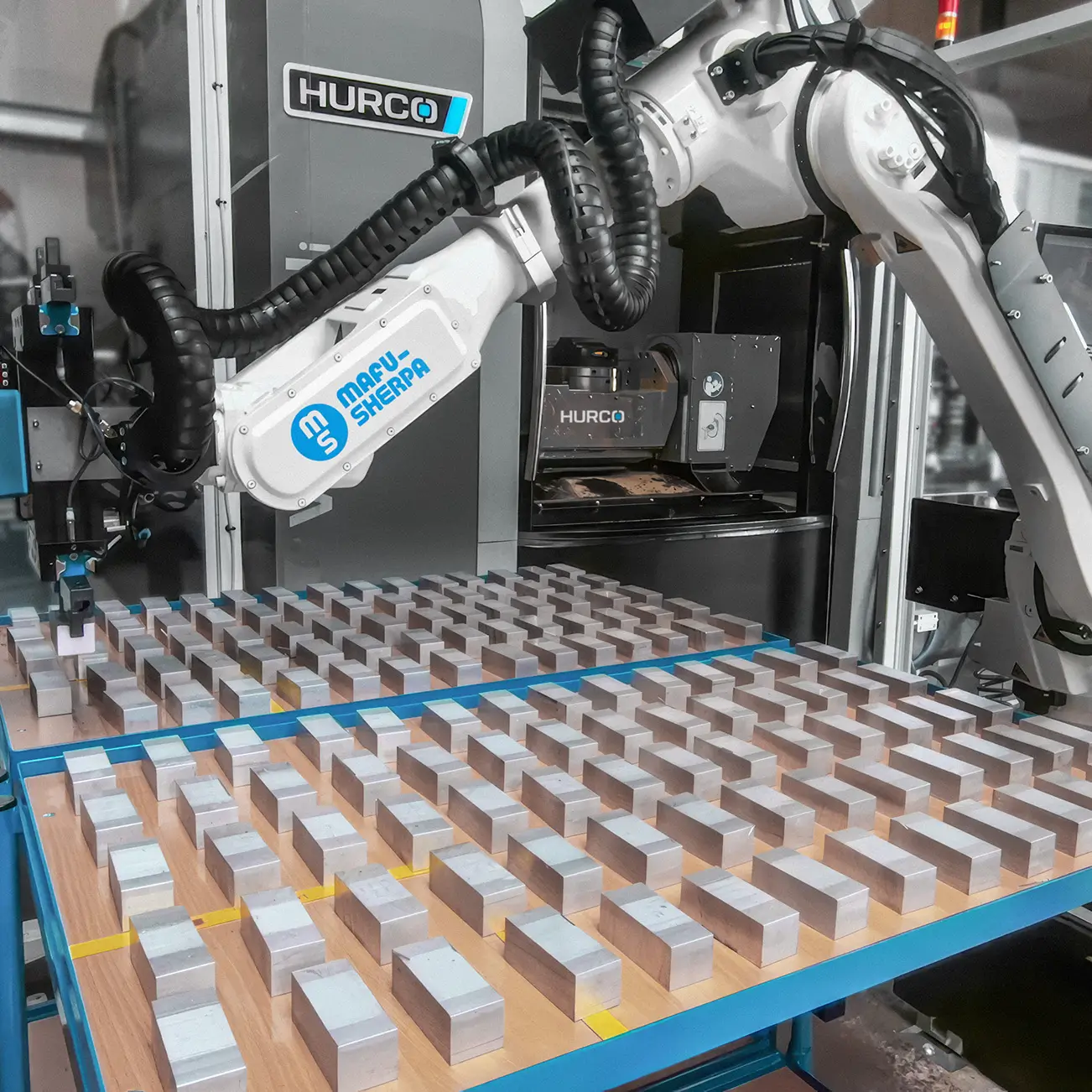

Discover the automation options of MAFU-SHERPA, with which you can fully automate the manufacturing process of your HURCO machine. Whether a new acquisition or an existing system, SHERPA's automation solutions can be easily integrated into the production of your HURCO machine to make your production future-oriented and economical. Thanks to the camera-based recognition system of the MAFU-SHERPA robots, production processes can be adapted to changing production conditions within minutes. SHERPA thus enables constant utilization of your HURCO machine and maximum productivity of your production!

Non-binding inquiry

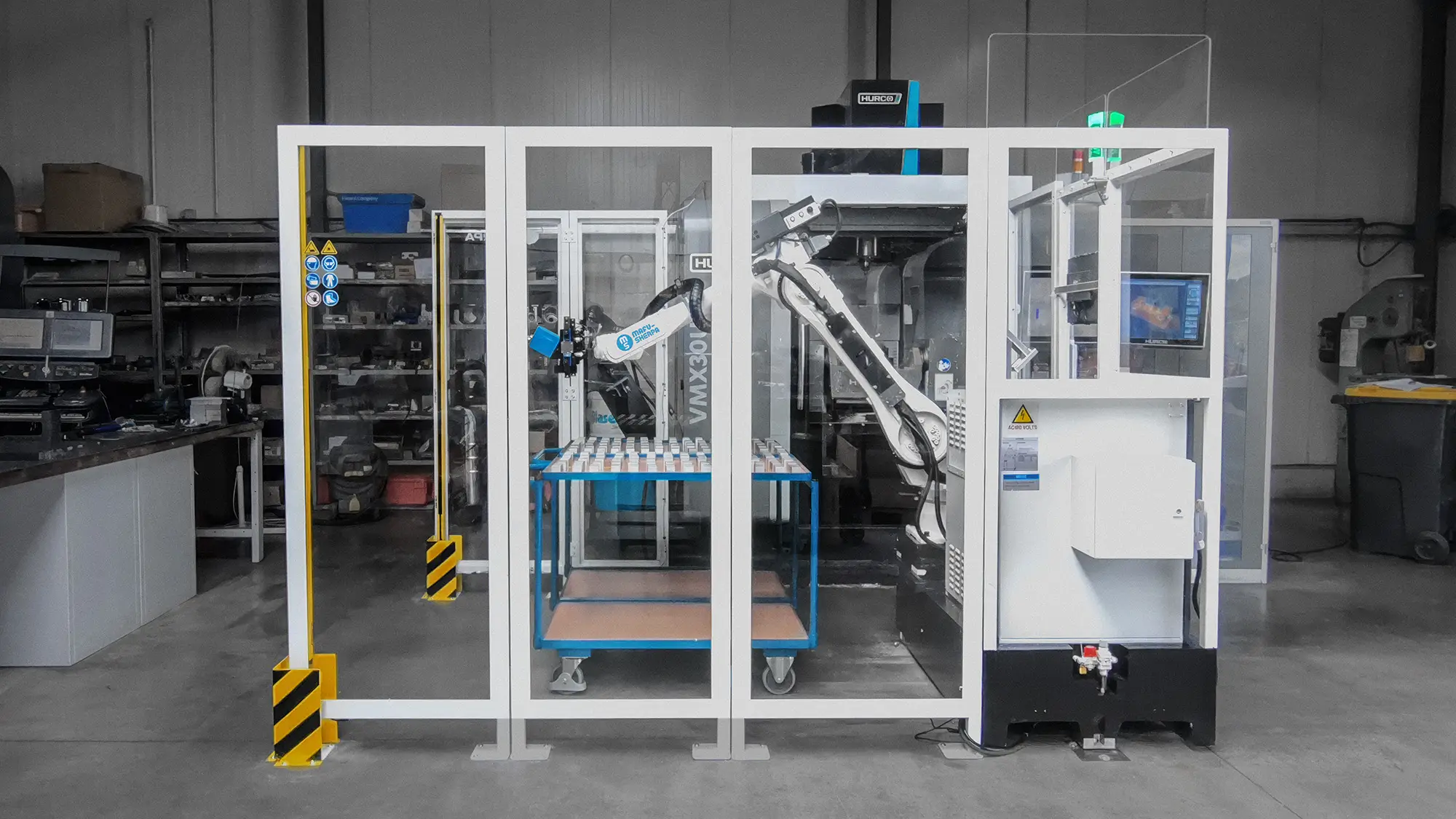

HURCO and MAFU-SHERPA are working together to automate production at TROST Zerspanungstechnik GmbH. Since 2021, a SherpaLoader® has been handling the entire workpiece handling process at TROST, from material provision to the finished part.

Learn more

The integration of SHERPA robots automates CNC Machining on your Hurco machine from the raw part to the finished workpiece. The automated transfer of raw parts from the Raw Material Staging to your Hurco machine eliminates manual tasks and maximizes spindle time in a coordinated process.

SHERPA robot systems fully automate your Hurco production. Manual intervention is significantly reduced. As a result, your Hurco machine runs around the clock without increased personnel costs!

Automated cleaning and precise positioning by SHERPA systems ensure consistent component quality and high process reliability.

Faster adaptation to changing production processes and the wide range of customization options offered by SHERPA systems also enable cost-effective automation of small and medium-sized series.

The robot systems from MAFU-SHERPA make your HURCO production more productive, more flexible and more economical - from single part production to series production.

The integration of MAFU-SHERPA robots automates CNC Machining on your HURCO machine from the raw part to the finished workpiece. The automated transfer of the raw parts from the Raw Material Staging to your HURCO machine eliminates manual activities and maximizes spindle time in a coordinated process.

MAFU-SHERPA robot systems fully automate your HURCO production. Manual intervention is significantly reduced. As a result, your HURCO machine runs around the clock without increased personnel costs!

Automated cleaning and precise positioning by MAFU-SHERPA systems ensure consistent component quality and high process reliability.

Faster adaptation to changing production processes and the wide range of customization options offered by MAFU-SHERPA systems also enable cost-effective automation of small and medium-sized series.

MAFU-SHERPA automation solutions can be integrated into any production process of your HURCO machine. Regardless of turning or milling operations, MAFU-SHERPA enables the automation of different parts. The modular design of the systems allows individual adaptation of the automation solution to your production process!

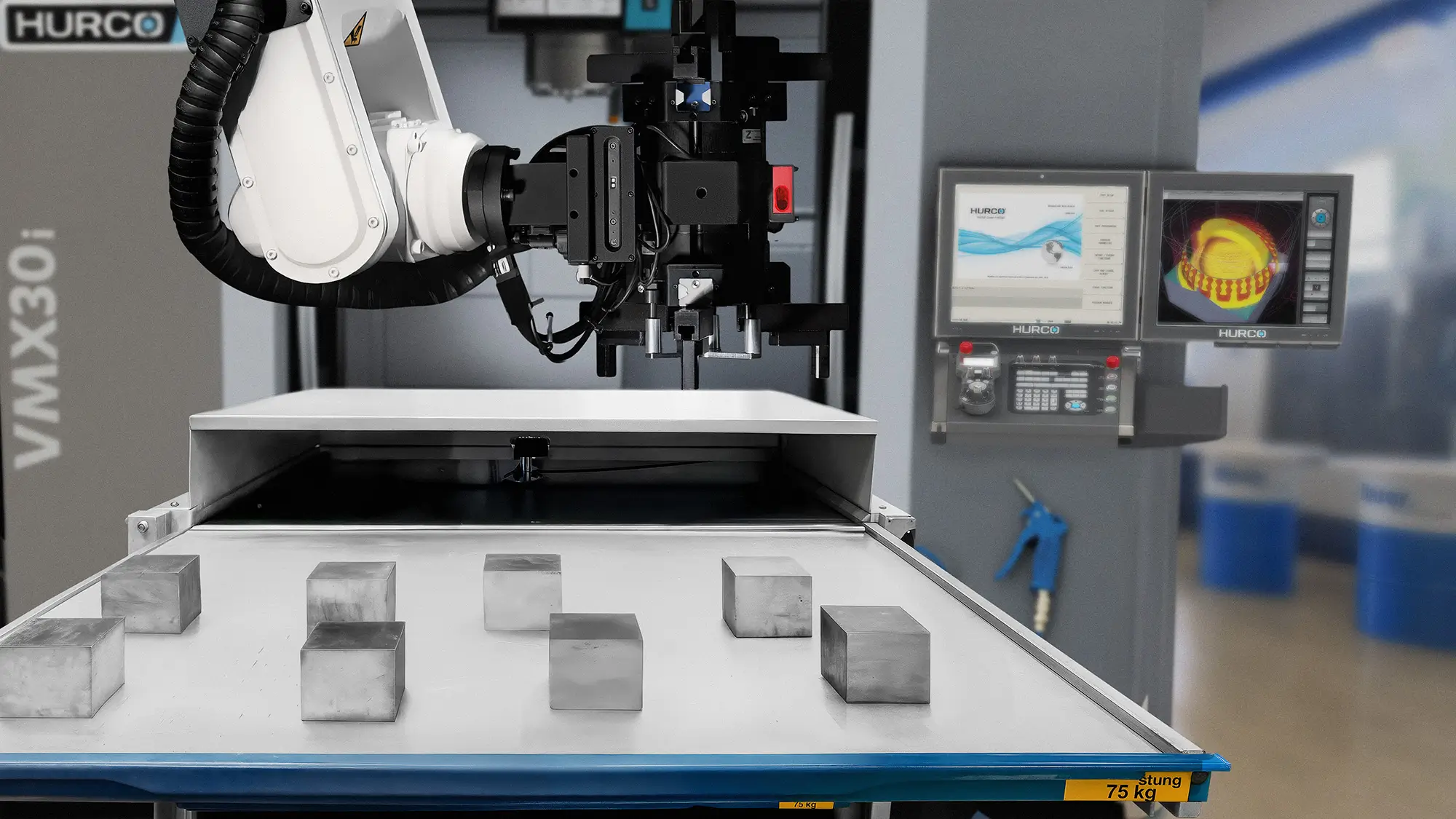

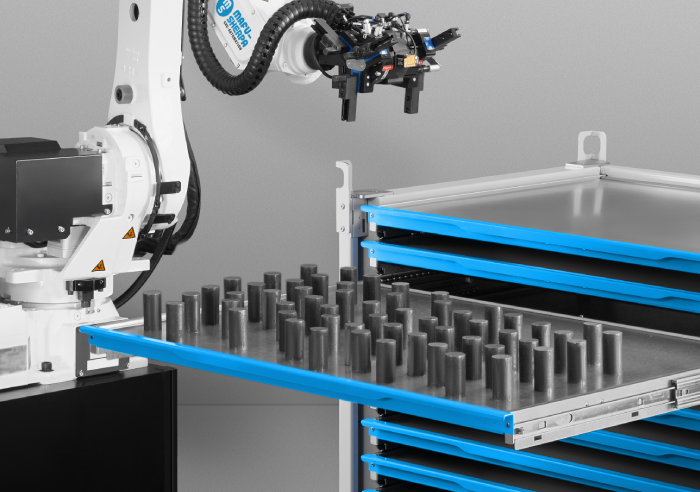

The automatic loading of the HURCO machines is made possible by the 3D camera laser system. The camera system recognizes the position of the workpieces regardless of their position, completely without matrices and position stops. Automatic recognition of the parts enables the production process to be adapted to New geometries quickly and easily, eliminating long set-up times.

In the event of a workpiece change, production loses important production time. Thanks to the modular design of MAFU-SHERPA systems, you can change over your system to the New workpiece within 5 minutes. This reduces non-productive time and maximizes the production time of your HURCO machine!

MAFU-SHERPA's solutions are as versatile as your process automation requirements! Regardless of component size or geometry and manufacturing process, the automation solutions from MAFU-SHERPA enable an individual concept for the material flow in your production process

The compatibility of your HURCO working machine with SHERPA's automation solutions makes it easy to integrate SHERPA's systems into your process. Thanks to the intuitive user interface on SHERPA's 17" touch display, your automated HURCO working machine can be operated without IT know-how.

The SherpaLoader® M7 and SherpaLoader® M12 models are suitable for the automation of machining processes for small and lightweight parts on your HURCO milling machine. These systems are characterized by their precise material handling, which makes your production more efficient in the long term.

For medium-heavy parts and larger quantities, SHERPA offers suitable automation solutions for your HURCO milling machine with the SherpaLoader® M25 and SherpaLoader® M50 models. The SherpaLoader®M25 is designed for workpieces weighing up to 18 kg, while the SherpaLoader®M50 can process workpieces weighing up to 38 kg.

The SherpaLoader® M88 and SherpaLoader® M225 models are particularly robust solutions for your HURCO milling machine for the automation of machining processes for heavy parts. Thanks to their high load capacity, stable gripper technology and the option of secure component positioning, even demanding production processes are supported efficiently and reproducibly.

The SherpaLoader® T7 and SherpaLoader® T12 models are ideal for Machining small and lightweight turned parts on HURCO lathes. They enable fast and precise transfer of the blanks to the spindle and their compact design ensures efficient use of the work area. This supports short non-productive times and consistently high component quality.

The SherpaLoader® T25 and SherpaLoader® T50 models are a robust and reliable solution for the production of medium-sized turned parts in large quantities. The SherpaLoader® T25 is suitable for workpieces weighing up to 18 kg, while the SherpaLoader® T50 can handle parts weighing up to 38 kg. Both systems combine stable component clamping with synchronized sequences, which extends the spindle run time and reduces personnel deployment.

The SherpaLoader® T88 and SherpaLoader® T225 models are used for particularly heavy turned parts or large-volume series. They are designed for high loads and ensure safe workpiece handling even with complex geometries. Thanks to their resilient mechanics and the possibility of end-to-end automation, even demanding production tasks are covered reliably and economically.

Would you like to automate the CNC manufacturing process of your HURCO machine, but do not want to purchase a new system? None of this is a problem! The automation solutions from MAFU-SHERPA can be integrated into the manufacturing processes of both New and existing systems. This ensures cost-effectiveness even when automating existing processes.

Thanks to the open source interface of your HURCO working machine, the SherpaLoader® models are fully compatible with the HURCO VMX, VC and TMX machine series. Both lathes and milling machines can be combined with the automation solutions without complex adaptations. This allows you to expand your existing systems efficiently and use them flexibly for different production tasks.

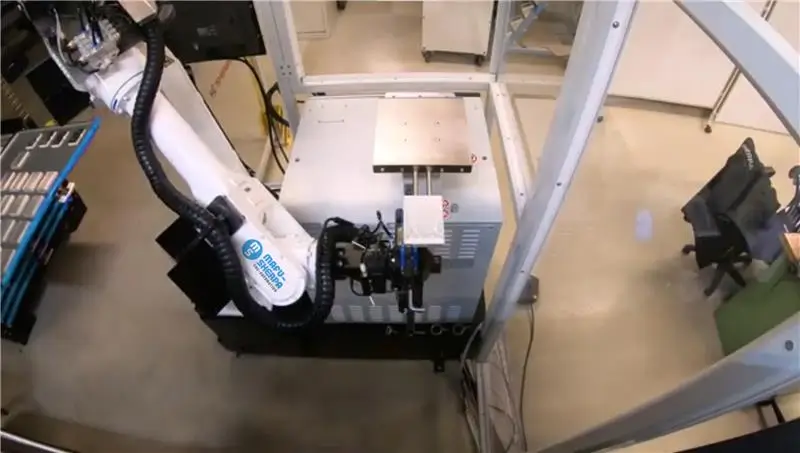

The SHERPA systems are integrated directly into the WinMax control system without any intervention. This eliminates the need for extensive software adaptations and the machines can still be used in their familiar operating environment. This not only reduces the set-up time, but also ensures uncomplicated commissioning. The automation is operated using the intuitive SHERPA operator display.

Existing turning and milling machines of HURCO can be retrofitted with the SHERPA models at any time. This means that even older systems can be economically upgraded to a higher level of automation without you having to invest in New machines. Retrofitting offers a sustainable way to increase the productivity and capacity utilization of your machinery.

Compared to comprehensive automation solutions, SHERPA systems represent a simple and practical alternative. They offer the essential functions for stable series production without unnecessary complexity in operation. This makes automation feasible even for small and medium-sized manufacturing companies.

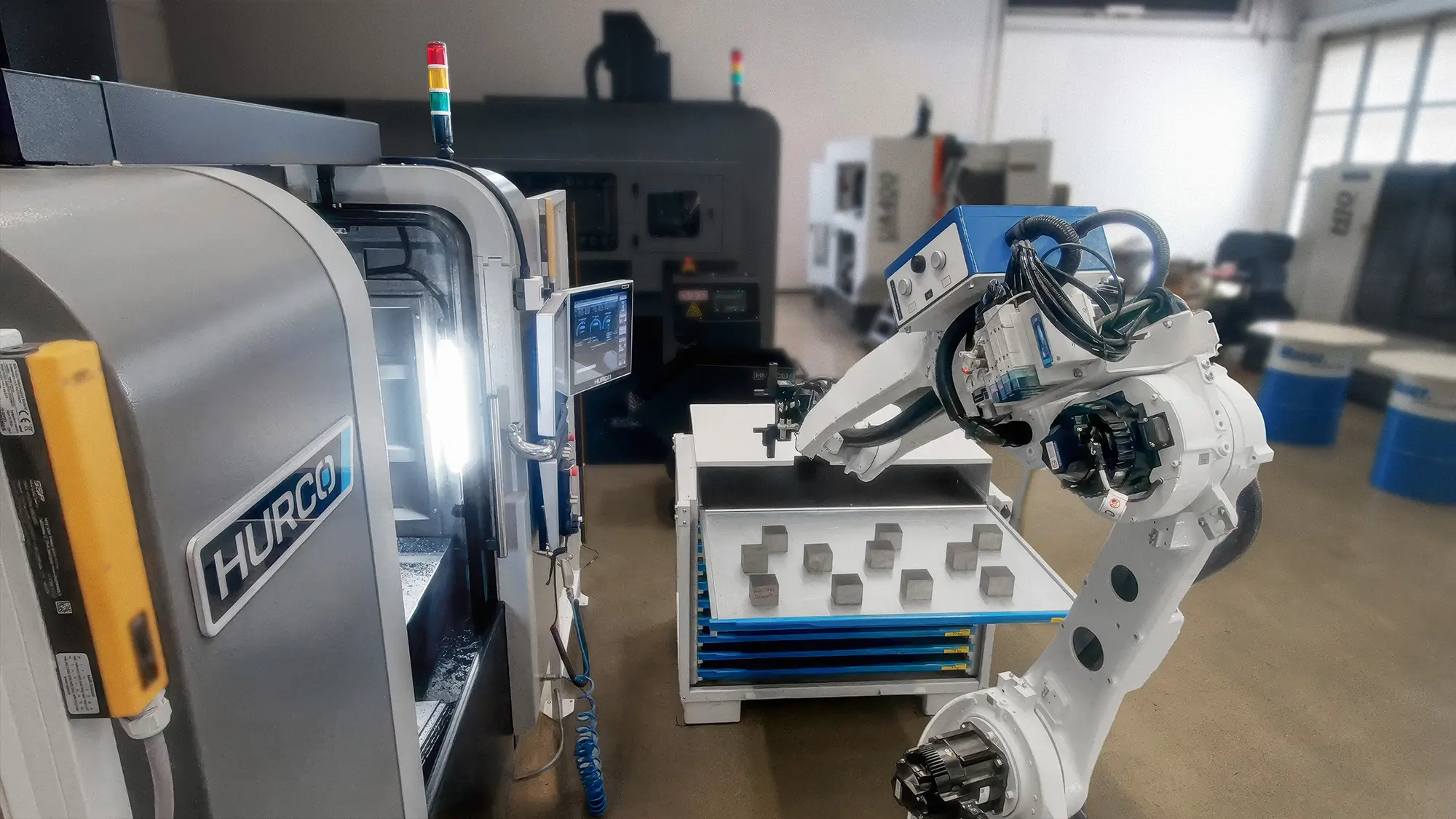

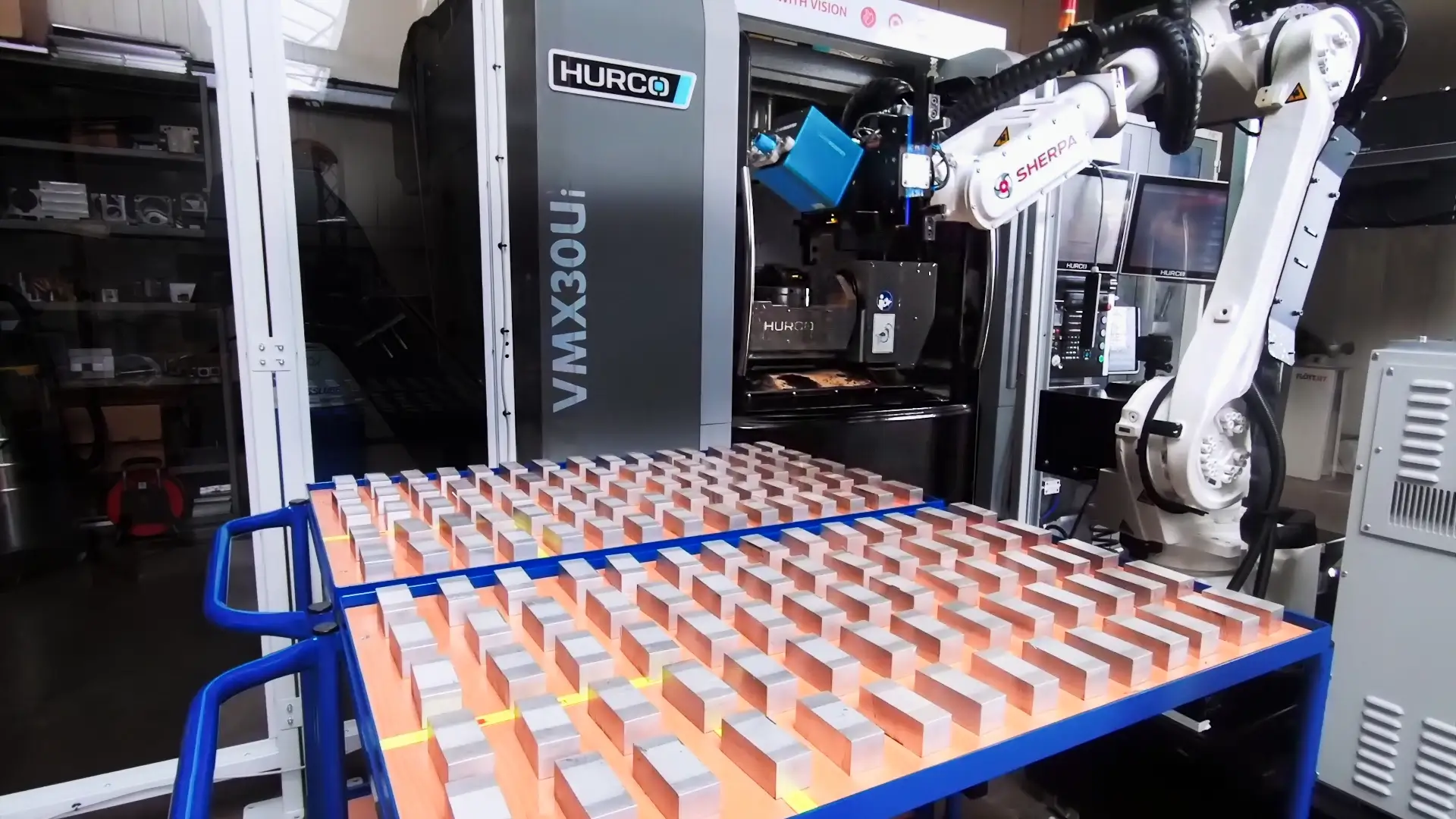

With the implementation of a SherpaLoader® M20 in the machining process of a HURCO VMX30Ui machining center, the production process was successfully automated. From the material supply of the raw parts to the depositing of the finished parts: The robot from SHERPA automates your entire manufacturing process. Learn more.

The way in which materials are provided plays a decisive role in automated production. With the Table Trolleys concept, raw and finished parts can be provided in a structured manner and are accessible at all times. In conjunction with SHERPA's camera-based recognition system, the workpieces are automatically detected and prepared for Editing. This eliminates much of the manual sorting and positioning work, while production can react flexibly to changing geometries. This ensures a consistently efficient material feed and reduces the effort involved in daily production.

The SHERPA systems can be integrated directly into the WinMax control environment without the need for additional adaptations. This means that the familiar operation of the HURCO machines is fully retained. A practical extension of the existing processes - without the operating personnel having to get used to it.

Whether compact milling machine, versatile turning center or large-format 5-axis system - the SHERPA models can be combined with all HURCO series. This provides flexible automation solutions for a wide range of production environments. Customers benefit from a scalable solution that is suitable for both small quantities and extensive series production.

The SHERPA systems are fully compatible with the WinMax control system and can be integrated directly into your existing processes via the DNC interface. None of the machine control system needs to be additionally adapted. Operators benefit from a familiar interface, while the automation works reliably in the background. The interaction ensures simple processes and a seamless expansion of production capacities.

With the MT-Connect interface, SHERPA systems are optimally prepared for the requirements of Industry 4.0. Process data can be recorded and evaluated in real time, creating transparency throughout the entire production process. This openness enables seamless documentation, better process monitoring and supports data-based optimization for greater efficiency.

By using an open interface architecture, SHERPA's automation solutions can be flexibly adapted to different production environments. This enables simple expansion of existing systems and individual adaptation to your customer-specific requirements. This gives users a high degree of future-proofing and investment protection.

The close cooperation between SHERPA and HURCO Germany ensures that the automation systems are optimally matched to your HURCO system. From planning to installation, the entire process is accompanied jointly. This provides you with a practical solution that is not only technically but also organizationally integrated into production. This partnership-based cooperation ensures smooth processes and sustainable added value in production.

By implementing the SherpaLoader® M25 in the machining process of a HURCO VMX 30i, production was successfully automated. Intelligent material provision forms the basis of machining automation. For maximum automated production, the material was supplied via a SpaceBox. The camera-based detection system records the position of the raw parts.

Automating your system with automation solutions from SHERPA enables continuous production around the clock - regardless of shift times or personnel availability. The robot works continuously and reliably, handles the components independently and ensures that the machine remains optimally utilized. Downtimes due to missing operators are eliminated, and even shifts without operators can be run safely. This not only increases productivity, but also improves profitability as additional personnel costs are avoided. Successful production automation at Liebl illustrates the influence of SHERPA systems.

The increasing shortage of skilled workers poses major challenges for many manufacturing companies. With SHERPA's automation solutions for your HURCO system, recurring and time-consuming work steps can be reliably automated. This significantly reduces the need for manual intervention. Skilled personnel can be deployed for more value-adding tasks. The robots take over the material supply, handling and process steps in a reproducible manner. Consistent quality is ensured. This reduces dependence on additional personnel and stabilizes production capacity.

Compared to complex automation systems, SHERPA systems offer an economically attractive alternative for your HURCO plant. Instead of having to invest in large and inflexible complete systems, you receive a tailor-made solution. Direct integration into the existing machine environment is guaranteed. The modular design enables step-by-step expansion without the need for high initial investment. As a result, your company benefits from an immediate increase in efficiency, better utilization of your machines and a faster return on investment.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

All common HURCO models can be automated with the SHERPA systems, from compact milling machines to larger turning and milling centers. The systems adapt flexibly to different machine configurations and enable consistent automation regardless of the series.

None of the WinMax controls need to be modified to integrate the SHERPA systems into your HURCO system. The robot solutions work directly with the existing machine logic, which minimizes the installation effort and significantly simplifies commissioning.

The installation of a SHERPA system on your HURCO machine is typically completed within 3 days. During this time, the robot is assembled, the interfaces to the control system are set up and the automation processes are tested so that the machine can go into automated production operation immediately after completion.

In an individual analysis, our experts work with you to determine which HURCO machines and processes are best suited for automation with SHERPA systems. Machine configuration, component sizes and production requirements are taken into account in order to tailor the automation solution precisely to your production.

Experience SHERPA's automation solutions directly on your machine in a practical demonstration. This allows you to see the benefits of precise material handling, synchronized sequences and process optimization directly and realistically assess the implementation in your production environment.

Or visit the HURCO showroom in Pliening, where the SherpaLoader M25 demonstrates how easy automation can be.

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us