Universal robot solution for all Makino machine types

MAFU-SHERPA offers an intelligent robot solution for the automated loading of Makino machining centers. With camera-controlled workpiece recognition and flexible material provision, your production becomes easier, faster and more economical. Customers receive ready-to-use automation that efficiently complements existing machines - regardless of model or year of manufacture. The solution increases productivity, reduces costs and makes your production fit for economical 24/7 operation.

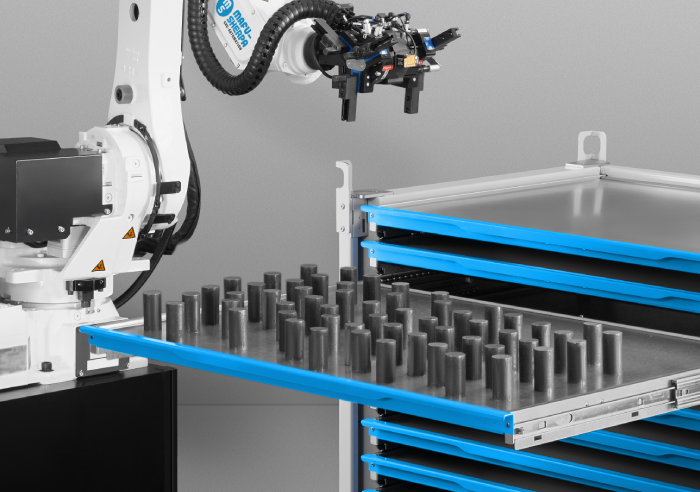

How it worksThe SherpaLoader® camera-controlled robot solution keeps Makino machining centers in continuous operation. Workpieces are fed automatically and precisely, keeping the spindle running Lengthwise and minimizing downtime. This increases productivity and ensures optimum utilization of the machine investment - even with existing systems.

Automated loading replaces time-consuming manual tasks. Employees can concentrate on more demanding tasks while the robot takes over workpiece feeding. This reduces personnel costs and increases production output at the same time.

The heart of the system, SherpaVision®, positions each workpiece precisely and reliably. Errors caused by manual loading are avoided, which increases process reliability. The automation of your Makino machine ensures consistently high quality, regardless of shift times or personnel changes.

The robot solution of MAFU-SHERPA enables flexible production without complex pallet systems. Even small and medium-sized series can be automated economically. This makes Makino machines versatile and increases competitiveness.

The SherpaVision® laser Vision System automatically and precisely recognizes workpieces without the need for pallets or fixed devices. In contrast to classic Makino pallet systems or FMS, production remains flexible and varied. Customers benefit from rapid adaptation to different workpieces and reliable part recognition.

The SherpaLoader® enables workpieces to be changed in less than five minutes. This eliminates the time-consuming retooling that is common with integrated pallet changers. Production remains dynamic and even small series can be automated economically. Compared to integrated pallet changers, you save valuable set-up time and increase flexibility.

Material is fed flexibly via various systems such as SpaceBox, Table Trolleys or Pallets. This allows the solution to be optimally adapted to the respective production environment. Customers are given maximum freedom in the organization of their workpiece supply.

The SherpaLoader® controls are easy to understand. None of the complicated FMS programming is required, so operation can be learned quickly. The EasyControl dialog control system offers an intuitive graphical user interface on a 17-inch touch display. This enables Faster and uncomplicated training for all employees.

For light workpieces, the models SherpaLoader® M7 und SherpaLoader® M12 are available. The M7 processes parts up to 4* kg in the size range: 10 x 10 x 10 mm to 150 x 150 x 150 mm, while the M12 reliably handles workpieces up to 8* kg. Both systems have a compact design and are perfect for precise parts and small series where fast and safe loading is crucial.

For medium workpiece sizes, the SherpaLoader® M25 and the SherpaLoader® M50 is the right solution. The M25 is designed for workpieces weighing up to 18* kg and covers a size range of up to 200 x 200 x 200 mm. The M50 goes one step further and can handle parts weighing up to 38* kg with dimensions of up to 300 x 300 x 300 mm. These models combine robust load capacity with flexible handling, making them ideal for a wide range of production orders.

When it comes to particularly heavy workpieces or large series, the

SherpaLoader® M88 and the

SherpaLoader® M225

is used. The M88 is suitable for Parts up to 73* kg and also covers the range up to 300 x 300 x 300 mm. The M225 is the high-load solution with a load capacity of up to 175* kg and project-specific customizable size ranges. Both systems guarantee maximum stability, consistent quality and reliable automation, even for demanding Parts.

* depending on workpiece center of gravity

The SherpaLoader® is compatible with all common Makino control systems and can be connected with little effort. New machines are integrated via standards such as Profibus, Profinet or EtherNet/IP. This universal interface makes retrofitting flexible, cost-efficient and possible for almost any Makino machine.

Even older Makino machines without an existing automation interface can be integrated. Communication takes place via free M functions and potential-free contacts, so that no expensive interface from the machine manufacturer is required. The solution is customized so that existing machines can also be automated. This ensures that the investment remains usable and productive in the long term.

Especially Makino machines without a prepared FMS interface can be automated. The SherpaLoader® is adapted to the specific project and enables reliable integration. This means that even existing machines benefit from modern robot technology and efficient production.

In contrast to rigid pallet systems, automation with the SherpaLoader® offers a flexible solution. Workpieces are recognized by camera control and fed directly. This makes production more varied and economical, especially for smaller series.

The process is clearly structured: The machine is analyzed first, followed by the technical design and finally commissioning. Retrofitting is planned in such a way that production interruptions are kept to a minimum. Customers receive a turnkey solution that is ready for immediate use.

With the SherpaLoader®, Makino machines can work around the clock - even without personnel on site. The camera-controlled workpiece recognition ensures that production continues reliably, even during night or weekend shifts. Customers benefit from a significantly higher utilization of their machines and a noticeable increase in production capacity.

The automation of Makino machines with SherpaLoader® reduces running costs as fewer personnel are required for monotonous loading activities. At the same time, capacity increases thanks to longer machine running times and fast changeovers. The result is an economical solution that reduces costs and increases competitiveness.

The investment in a SherpaLoader® quickly pays for itself. Reduced personnel costs, longer machine running times and consistent production quality result in a clear economic advantage. The purchase usually pays for itself within 12 months. Customers benefit from a short amortization period and a sustainable increase in competitiveness.

The SherpaLoader® reliably automates the a1 series of Makino and ensures continuous workpiece feeding. The camera-controlled detection makes production flexible and reduces downtime. Customers benefit from higher capacity utilization and economical automation, even for smaller series.

Makino 5-axis centers can be efficiently retrofitted with the SherpaLoader®. The flexible material supply via SpaceBox or Table Trolleys enables quick adaptation to different workpieces. This makes production more varied and significantly increases productivity.

Vertical 3-axis centers of Makino can also be easily automated. The SherpaLoader® takes care of precise loading and ensures consistent quality. Customers receive a simple solution that does not require complex FMS programming.

The SherpaLoader® flexibly automates Makino's D, DA and V series. Workpieces can be changed in just a few minutes, so that even jobs with many variants can be implemented economically. This increases competitiveness and makes production future-proof.

The T-series of Makino specializes in titanium processing and places high demands on automation. The SherpaLoader® offers a robust solution for Lengthwise processing. Customers benefit from stable processes and reliable automation, even with demanding materials.

For the iQ series and the V22 model, the SherpaLoader® offers precise automation in the field of micromachining. The smallest workpieces are reliably detected and fed so that production remains constant and error-free. This makes the solution ideal for high-precision applications with the highest quality requirements.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

The SherpaLoader® is compatible with all standard Makino machining centers. Both horizontal and vertical machines, including 3- and 5-axis centers, can be retrofitted. Even specialized series such as the T or iQ series can be automated. This provides customers with a universal solution for almost any Makino machine.

The automation comes from MAFU-SHERPA and is integrated independently of the machine manufacturer. Retrofitting is carried out via standardized interfaces, without interfering with the core functions of the machine. This means that the Makino warranty remains unaffected, while production becomes more productive at the same time.

Implementation is planned in such a way that ongoing production is hardly affected. Many steps can be carried out in parallel with production so that downtime is reduced to a minimum. Customers benefit from a fast and smooth integration.

Compared to pallet systems, the SherpaLoader® offers a flexible, retrofittable and cost-effective solution. Workpieces are recognized by camera control and fed directly, without rigid devices. This makes production more varied and economical, especially for smaller series.

The SherpaLoader® is also suitable for demanding applications such as titanium processing with ADVANTiGE™. The robust design and precise workpiece detection ensure stable processes. Customers receive reliable automation even with difficult materials.

With the SherpaLoader®, Makino machines can be operated around the clock. Night and weekend shifts run unmanned, while quality remains constant. This increases productivity and makes production significantly more economical.

MAFU-SHERPA offers comprehensive service and support for robot automation. The entire process is supported, from commissioning to training and maintenance. Customers receive reliable support that ensures the long-term success of the automation. The SherpaLoader® also has a remote maintenance interface for remote support. If necessary, its control system can be diagnosed and optimized.

Before implementation, each Makino machine is examined in detail to find the right automation solution. The analysis is uncomplicated and practical, so that the requirements are quickly recorded. Customers receive a clear recommendation that is precisely tailored to their production situation.

The functions of the SherpaLoader® can be experienced directly in a live demonstration. The demonstration shows how workpieces are recognized by camera and fed automatically. Customers can immediately see the benefits of automating their Makino machining center in practical use.

Based on the analysis, an individual offer is created that is tailored precisely to the Makino machine in question. Customers receive a clear cost overview and a solution that is economical and future-proof.

MAFU-SHERPA accompanies the entire process, from the initial consultation to the technical design and commissioning. Customers benefit from end-to-end support and a turnkey solution. The automation is implemented smoothly and is ready for immediate use.

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us