Universal robot solution for all Nakamura-Tome machine types

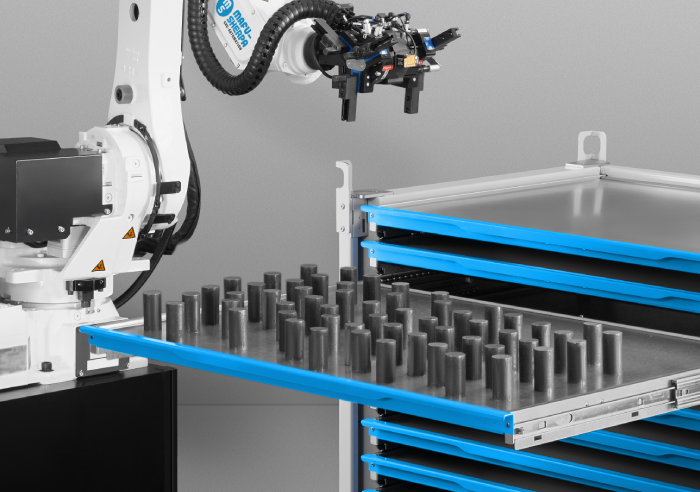

MAFU-SHERPA offers an independent automation solution for Nakamura-Tome machines. The SherpaLoader® takes over the workpiece feed with a robot arm and ensures a continuous production flow. The camera-controlled technology recognizes parts precisely and positions them reliably. The perfect robot for your Nakamura-Tome.

How it worksThe SherpaLoader® keeps the machine running continuously. Workpieces are fed automatically so that the spindle time is used optimally. Downtimes due to manual loading are eliminated, which significantly increases the utilization of the machine. The result is a higher production volume with the same machine capacity.

Automation significantly reduces the need for operating personnel. A robotic arm takes over loading, while the machine works Lengthwise and more efficiently. This means that skilled workers can be deployed for more value-adding activities. At the same time, the costs per manufactured part are reduced, which increases competitiveness.

The camera-controlled system recognizes each workpiece exactly and positions it with high precision. As a result, the production quality remains consistently high - regardless of the batch size. Errors caused by manual handling are avoided, which reduces rejects and increases process reliability. Customers benefit from consistent quality over long production runs.

Automation for Nakamura-Tome is not only suitable for large series. Small and medium quantities can also be automated economically. Short changeover times make production flexible and efficient. This means that changing jobs can be implemented without long downtimes, which makes production planning easier.

The SherpaLoader® uses a 3D camera laser system for workpiece detection. None of the gantry magazines or vision sensors from Nakamura require fixed positioning. The system recognizes parts flexibly and automatically adapts to different shapes and sizes. This makes handling easier and significantly reduces set-up time.

A workpiece change takes less than five minutes. Only the gripper dimensions are adjusted - there is no need for time-consuming magazine or pallet changes. This saves time and maximizes machine uptime. This flexibility is a decisive advantage, especially for frequently changing jobs.

Workpieces can be provided via various systems: SpaceBox, Table Trolleys or Pallets. This flexibility makes it easy to adapt to different parts and batch sizes. Users can choose the right material concept depending on their production requirements and thus optimize their processes.

It is controlled via an intuitive dialog interface. None of the operators need any special programming knowledge for Nakamura machines. New Jobs can be set up quickly and easily. This reduces the training period and makes automation attractive for smaller companies too.

The SherpaLoader® can automate new machines as well as existing machines. Thanks to its universal interface, it can be easily connected to different control systems. This enables rapid integration without long adaptation phases and makes automation particularly flexible.

Machine tools have had standardized bus interfaces for robot automation for around 15 years. The SherpaLoader® supports the widely used Profibus, Profinet and EtherNet/IP standards. This ensures a simple and secure connection, regardless of the age of the machine.

Even machines without factory robot preparation can be automated with the SherpaLoader®. MAFU-SHERPA uses M functions and potential-free contacts for this purpose. In this way, retrofitting is implemented in accordance with the guidelines without the need for costly adaptations by the machine manufacturer.

The SherpaLoader® offers a flexible alternative to the permanently integrated gantry loader. The external solution can be converted more quickly and requires less space. This makes it particularly suitable for existing systems that are to be automated at a later date.

Retrofitting is structured and efficient. A clear process is followed from planning to installation and commissioning. This means that production can be resumed quickly and the benefits of automation are available immediately.

For the automation of Nakamura-Tome lathes with lighter chuck parts and shorter shafts, the SherpaLoader® T7 and SherpaLoader® T12 are ideally suited. They enable precise feeding of small workpieces and ensure uninterrupted operation without manual intervention. This increases efficiency and reduces downtimes.

The SherpaLoader® T25 and SherpaLoader® T50 offer a reliable solution for the automation of medium-heavy Cylinders and Shafts. With load capacities of up to 18 kg* (T25) and 38 kg* (T50), they are ideal for modern production environments. They ensure consistently high quality and significantly reduce the workload on operating personnel.

For Lengthwise and heavier turned parts, the

SherpaLoader® T88 and

SherpaLoader® T225

are available. They offer the necessary load capacity and precision to handle even large parts safely. This ensures reliable, continuous operation - even with high loads and demanding production orders.

* Handling weight depending on workpiece center of gravity

For the automation of Nakamura-Tome milling machines and machining centers with light to medium-heavy workpieces, the models SherpaLoader® M7 and SherpaLoader® M12 are ideally suited to this. They impress with their precise handling and efficient processes, which extend machine runtimes and make production more economical. They provide a flexible and reliable solution, especially for smaller series or frequently changing jobs.

The SherpaLoader® M25 and SherpaLoader® M50 are the ideal choice for Nakamura-Tome machining centers for medium-heavy applications. The M25 moves workpieces up to 18 kg, while the M50 is designed for parts up to 38 kg. Both systems offer stable automation that increases productivity while reducing operator workload.

For loading heavy workpieces or manufacturing large series, the

SherpaLoader® M88 and

SherpaLoader® M225

is the right solution. They offer high load capacity and maximum stability so that even demanding production environments can be reliably automated. These systems are particularly suitable for companies that rely on continuous operation and high volumes.

* Handhabungsgewicht abhängig vom Bauteilschwerpunkt

The SherpaLoader® uses a 3D camera laser system to recognize workpieces directly where they are placed - on Table Trolleys, Pallets or in the SpaceBox. In contrast, gantry magazine systems of Nakamura require fixed storage positions and fixtures. The camera-controlled principle saves set-up time and makes production more variable, especially with frequently changing Parts.

The SherpaLoader® systems are external solutions that are connected independently of the machine manufacturer. They can automate both new and existing machines and support common interfaces such as Profibus, Profinet and EtherNet/IP. Nakamura, on the other hand, relies on integrated gantry robots that are permanently connected to the machine. These offer close OEM integration, but are less flexible when it comes to retrofitting.

With the SpaceBox of MAFU-SHERPA, workpieces can be provided in a space-saving and variable manner. The system is not limited to rigid processes and can accommodate different workpiece sizes. In contrast, Nakamura relies on classic conveyor belt or magazine solutions that are optimized for specific processes. The SpaceBox concept offers more freedom and reduces the space required in production.

An extension module enables the automatic turning of workpieces directly during the loading process. This enables twin-spindle machines to Machining both sides of a Part without manual intervention. This saves time, reduces sources of error and enables end-to-end complete machining.

The SherpaLoader® can be equipped with an integrated cleaning station. Workpieces are freed of chips and cooling lubricants after Machining before they are unloaded. Clean parts ensure quality and prevent faults in downstream processes.

An alignment station ensures that workpieces are precisely pre-positioned. This precise alignment is crucial for ChronoCut-optimized Machining and guarantees consistently high accuracy. The module reduces rejects and increases process reliability.

Additional modules extend the manufacturing process with functions such as Marking or Measure. Workpieces can be marked or inspected directly after Machining. This makes the production chain more efficient and automates additional work steps.

If you want to automate your DMG MORI milling machine and need to move light to medium-weight workpieces, the SherpaLoader® M7 and SherpaLoader® M12 models are the ideal solution. They impress with their high precision and efficient processes, which support your production processes in the long term.

The SherpaLoader® M25 and SherpaLoader® M50 offer reliable automation solutions for DMG MORI milling machines in medium-heavy applications: The M25 handles workpieces weighing up to 18 kg, while the M50 is designed for workpieces weighing up to 38 kg.

When it comes to loading heavy workpieces or producing large series, the SherpaLoader® M88 and SherpaLoader® M225 are the ideal partners. These systems guarantee stability, reliability and a high load-bearing capacity - essential for demanding production environments.

The SherpaLoader® enables production without constant operation. Machines can continue to run overnight or at weekends without the need for personnel to be on site. This significantly increases output while reducing production costs per part. Companies benefit from higher machine availability and better utilization of their investments.

Automation not only reduces personnel costs, but also the costs for additional machines. With the SherpaLoader®, complete machining processes can be mapped on a single machine. This saves space, energy and investment in Next machines. At the same time, production is made more efficient and economical.

The WT series is designed for high productivity and benefits in particular from the flexible automation of the SherpaLoader®. Workpieces are fed continuously so that both turrets are optimally utilized. The robot solutions adapt to different machine sizes and ensure stable production.

The AS series is one of Nakamura-Tome's best-selling machines. With the SherpaLoader®, loading is automated and the machine remains permanently productive. The system is ideal for small and medium-sized workpieces and guarantees a significant reduction in operator workload.

The WY series with Y-axis allows complex Machining. The SherpaLoader® supports these machines with precise handling and fast changeover. This means that demanding production tasks can be carried out efficiently without complicating operation.

Multitasking centers with automatic tool changers benefit from continuous loading by the SherpaLoader®. Workpieces are reliably fed so that the machine can make full use of its multitasking capabilities. This increases efficiency during complex Machining.

Single-turret machines can also be automated with the SherpaLoader®. Workpieces are handled with precision, ensuring that production remains stable and efficient. With the NT-Flex+ in particular, automation ensures maximum precision in the Swiss-style area.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

The SherpaLoader® is compatible with almost all Nakamura-Tome series - from twin-spindle to ATC multitasking and single-turret machines. Both new machines and existing systems can be connected. The flexibility of the interfaces ensures that a wide variety of models can be automated.

Retrofitting is carried out in accordance with the guidelines and without interfering with the machine control system, which would affect the warranty. Customers retain the manufacturer's warranty on their machine, while external automation brings additional benefits.

The implementation of the SherpaLoader® is planned in such a way that production interruptions are kept to a minimum. Many installations can be prepared in parallel with ongoing production. This means that the machine is quickly ready for use again and the changeover takes place without lengthwise downtimes.

Compared to permanently integrated gantry systems, the SherpaLoader® offers more flexibility. It can be converted Faster, requires less space and can also be used with existing machines. This makes it particularly economical for companies with changing jobs.

With the SherpaLoader®, machines can be operated unmanned - even at night or at weekends. This significantly increases output and enables genuine 24/7 production. This allows companies to make optimum use of their machine capacity.

MAFU-SHERPA offers comprehensive service and support for automation. This includes maintenance, training and Faster assistance in the event of a fault. Customers benefit from a reliable partner who provides long-term support for the automation solution.

Every production process has its own requirements. To ensure that the automation fits perfectly, the SherpaLoader® is tailored to the respective production process. Workpiece sizes, batch sizes and production targets are incorporated directly into the solution. The process is straightforward and ensures that the machine can be automated quickly and efficiently.

The functions of the SherpaLoader® can be shown in a practical demonstration. This shows how workpieces are recognized, precisely handled and efficiently fed using camera control. Interested parties will get a clear impression of the benefits of automation and experience how production processes can be simplified and accelerated using the SherpaLoader®.

MAFU-SHERPA accompanies the entire process, from the initial idea to the finished solution. Planning, installation and commissioning are structured and efficient. As a result, the switch to automated production is implemented smoothly and the benefits are available immediately.

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us