Universal robot solution for all common Victor machine types

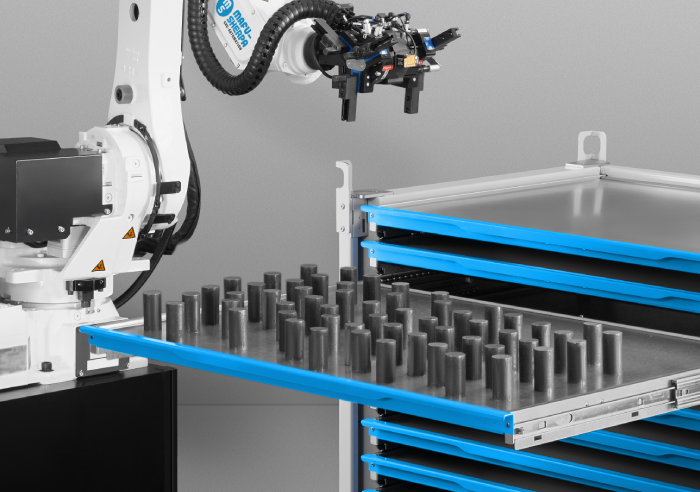

With the SherpaLoader®, you can automate your Victor CNC machines reliably and efficiently. The camera-controlled robot solution is easy to retrofit and increases productivity, process reliability and ease of use. This makes your production more flexible, more economical and less dependent on manual intervention.

How it worksAutomatic loading keeps the spindle active even outside regular working hours. Workpieces are fed and removed precisely, minimizing non-productive times. The result: significantly longer machine running time and maximum utilization of your Victor machine.

The SherpaLoader® takes over monotonous tasks such as loading and unloading completely autonomously. This relieves the operating personnel and allows them to concentrate on value-adding tasks. At the same time, the costs per Part are reduced - a decisive advantage in times of a shortage of skilled workers.

Every movement is reproducible and with consistent precision. Workpieces are automatically recognized, positioned and clamped. This means that quality remains consistently high - regardless of shift operation or personnel changes.

Thanks to fast retooling and flexible material provision, automation remains economical even with varying batch sizes. Even small series can be produced efficiently without long set-up times or complex adjustments.

The integrated 3D laser Vision System SherpaVision® recognizes workpieces autonomously and accurately. Different shapes, materials or layers are reliably identified - for error-free loading.

None of the complex programming is required to switch to new parts. The robot cell adapts flexibly and is ready for use in just a few minutes. Ideal for agile manufacturing processes.

Whether sensitive plastic parts, sawn cuboids or metal blanks - the provision is flexible. The robot automatically recognizes the position and picks up the workpieces ready for clamping.

It is controlled via an intuitive user interface on a 17-inch touch display. Predefined sequences and visual assistance functions make operation safe and easy, even without robotics experience.

The compact SherpaLoader® T7 and SherpaLoader® T12 handle small to medium-sized turned parts with precision and ensure consistently high quality. Thanks to the camera-controlled workpiece recognition, even varying geometries can be reliably automated.

The SherpaLoader® T25 and SherpaLoader® T50 models are designed for larger workpieces and offer a robust solution for medium-sized series. They combine high load capacity with fast cycle times and enable economical production even with demanding materials.

The SherpaLoader® T88 and SherpaLoader® T225 are used for heavy turned parts. Process reliability is guaranteed even with large quantities.

With its universal interface, the SherpaLoader® can be connected to all common turning and milling machines - regardless of their year of manufacture. This means that the same SherpaLoader® can be used to retrofit an older existing machine or to automate a new machine.

The SherpaLoader® M7 and SherpaLoader® M12 are specialized in handling light workpieces. They enable fast workpiece changes and ensure consistent processing quality - ideal for plastic housings or aluminum parts.

The SherpaLoader® M25 and SherpaLoader® M50 models offer the right solution for medium-sized workpieces. They combine flexibility with high precision and are ideal for varying batch sizes.

The SherpaLoader® M88 and SherpaLoader® M225 are designed for heavy workpieces. Their robust construction guarantees process reliability even under high loads.

The SherpaLoader® systems are compatible with common control systems such as FANUC and SIEMENS. This means that even older Victor machines can be easily connected without the need for additional hardware.

Adaptation by the machine manufacturer is not necessary. The robot solution is integrated externally and works independently of the machine design. This saves time and costs during implementation. The SherpaLoader® is compatible with the common Profibus, Profinet and EtherNet/IP standards.

Machines without an existing bus interface are automated via M functions and potential-free contacts. The SherpaLoader® comes with all the necessary components and makes your existing machines fit for the future.

Whether it's a lathe, machining center or multitasking center - the retrofit solution is available for all common Victor series. This allows you to automate your entire production step by step.

Thanks to camera-controlled detection, there is no need for special clamping or positioning devices. The robot automatically identifies each workpiece and positions it precisely. This saves set-up time and increases flexibility in production.

Whether round, angular or complex parts - the system reliably recognizes different geometries. This means that even changing jobs can be automated without additional adjustments.

The robot solution adapts independently to different sizes. Small, medium and large parts can be processed without retooling. This keeps your production flexible at all times.

The integrated 3D laser system ensures the exact positioning of each workpiece. This prevents processing errors and ensures consistently high quality - regardless of the batch size.

In principle, all standard Victor machines can be automated with the SherpaLoader®. These include lathes from the Vturn series, machining centers from the Vcenter series and multitasking centers from the VMT-X series. Older models can also be easily retrofitted using retrofit solutions.

The retrofit is carried out externally and does not require any modification by the manufacturer. This does not affect the machine warranty.

From small precision parts to heavy castings, the SherpaLoader® series covers a wide spectrum. Depending on the model, payloads of a few kilograms to 175 kg are possible. The handling weight depends on the component's center of gravity. This means that there is a suitable solution for almost every production requirement.

In many cases, the robot cell can be integrated without Lengthwise downtime. Mechanical connection and commissioning are planned in such a way that ongoing processes are only minimally affected. The exact coordination takes place individually as part of the project planning.

Commissioning can be realized in a short time. In best-practice projects, the complete installation, including training, has already been successfully completed in just three days.

Every production facility has its own requirements. Together, we examine your machine and parts - and develop a simple solution that immediately fits into your production.

Arrange a presentation! To make the advantages of automation tangible. You will experience the SherpaLoader® in real use and see how workpieces are automatically recognized, positioned and edited. This will give you a practical impression of how the solution works in your production.

Call us:

+49 711 2525 744 - 0

Write to us:

info@mafu-sherpa.com

It is always our pleasure to have the system set up and started without any instructions from the operator.

Give us a call

write us